B5L Section - 58. Something you can do for less cost that may solve this problem is to take the pulley off and add a setscew 90 degrees from the existing setscrew.

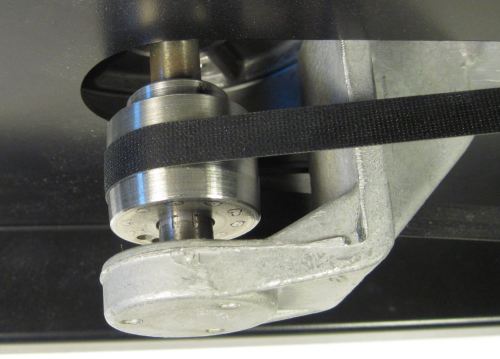

Timing Belts In The Car Play Such A Very Important Role But They Are Rarely Considered Whenever It Is Time For Maintenance And Repairs Timing Belt Belt Pulley

Timing Belts In The Car Play Such A Very Important Role But They Are Rarely Considered Whenever It Is Time For Maintenance And Repairs Timing Belt Belt Pulley

It doesnt matter which pulley you choose whether you have a belt attached to it or not.

How far can v belt pulleys be missed aligned. 18022021 Hold 1 end of the string on top of the belt or 1 of the pulleys. One of the biggest burdens today for professional technicians and do-it-yourselfers is belt noise and the No. 1 cause of belt noise is misalignmentThere are two distinctively different types of belt noise Chirp and SquealEach has its own unique characteristics causes and solutions.

30072014 Diagnosing Misalignment and Belt Noise July 30 2014 at 1054am. Dont crimp belts beyond the smallest recommended pulley radius for that belt. If the marks do not align remove the belt and install it again.

27012016 Turn the crankshaft pulley 2 revolutions clockwise from TDC to TDC. DO NOT UNDER ANY CIRCUMSTANCES install belts by prying them onto pulleys by any forcible method. Drastic belt slip instability or damaged undercord material.

30112015 Chirping can be due to misalignment of the drive belt but could also be due to pulley misalignment worn pulley bearings worn belt ribs contamination from oil coolant power steering fluid brake cleaner belt dressing or other substances. 01052002 Minimum recommended pulley diameters must be noted. In this video we learn how to calculate the belt length as well as the distance between the two pulleys This is common in the HVAC and building services indu.

BELT FAILURE MODES AND PROBABLE CAUSES SledMotorClutchBelt Symptoms. Kevlar V Belt Sections. Pretension belts with the proper recommended tension.

Belt will ride lower in the primary pulley at high speed. Install new belts on the pulleys so that the slack sides of all belts are on the same side at either top or bottom of the drive. Squealing is usually caused by slipping between the belt and the pulleys.

Per foot of drive center distance. 24082012 Also note that in a properly designed belt drive there should be a minimum of six teeth in mesh and at least 60. Youll also need to measure the width and depth to determine which section v belt you have.

Hopefully this is clear from the pictures. For example if your small pulley is 80mm diameter and spins at 1000 RPM and you need to find the second pulley size to spin it at 400 RPM Enter Pulley1 80 Pulley 1 RPM 1000 Pulley 2 RPM 400 and hit Calculate to find the second pulley. 26052019 The second part the distance between the pulleys is if you already know what length belt you need and also you know the diameter of both the pulleys.

27012019 For decades drive belts V-belts multi-vee-belts and serpentine belts have been used to transmit power from the engine crankshaft pulley to accessories such as the power steering pump air conditioning compressor water pump or cooling fans. A4L Section - 12. Also keep in mind belts do stretch and unfortunately there is no specific value for how much a belt can stretch.

This method results in varying degrees of accuracy when the pulleys are of different thickness brands or kinds eg. 21102015 Seek 164 0015625 of an inch deflection for every 1 inch of belt span length. Even though the March information via Summit says this bracket mounting will work for either V-belt or serpentine Im thinking its only for V-belt.

07092020 The crank and water pump pulleys line up OK but the alternator pulley is about 1-18 inch too far back. Not hard to do if you use a center punch to make a divot so the drill bit doesnt wander. De-tension the motor to allow this fitting to be effected without undue.

Align shafts and pulleys to prevent belt-tracking forces and belt edge wear. Belt will be pulled too far down into the secondary. This extends life and prevents belt ratcheting or tooth jumping.

30072008 Misalignment for synchronous Polyflex and Micro-V belts should be within 14 degree or 116. For example on a 3V-section V-belt pulleys smaller than 265 in. 100 mils per foot can easily be seen by anyone same as 12 degree or 30 minutes angle - no need for alignment tools as long as you can.

The more you tension a belt the faster it will wear out. You can do it manually OR you can download our excel sheet. Loss of top end speed.

28092003 Machined pulleys is the best bet. Check that the alignment marks on the camshaft timing pulleys are aligned with those on the No. 3L Section - 38.

30112011 The main disadvantage is that the face of the pulley is the only reference point. Then replace the pulley and tighten both setscrews. One single-belt pulley and one multiple-belt pulley or when the faces are not well finished.

Toothed timing belts and timing chains too are used to transmit power from the crankshaft to the camshafts and some. Belts should be fitted by hand pressure only. This means that only the faces of the pulleys are aligned with each other.

2 timing belt cover. 3 timing cover gasket cover and retaining bolts. For example if the span length is 50 inches the desired belt deflection is 0015625 164 of an Inch X 50 078125 or 2532 of an inch.

Belt will ride lower in the secondary pulley at engagement. But youre not sure exactly what the distance should be between them. Calculate Pulley Belt Length.

If you know any 3 values Pulley sizes or RPM and need to calculate the 4th enter the 3 known values and hit Calculate to find the missing value. Of belt wrap around the drive pulley. Take the end of the string and choose a pulley to place it on top of.

Use 1 hand to hold the string in place so it doesnt move when you take your measurements.

5 Step Sheave Pulley Alignment Procedure Motion Graphic Youtube

5 Step Sheave Pulley Alignment Procedure Motion Graphic Youtube

Pin On Timing Pulley Manufacturer In India

Pin On Timing Pulley Manufacturer In India

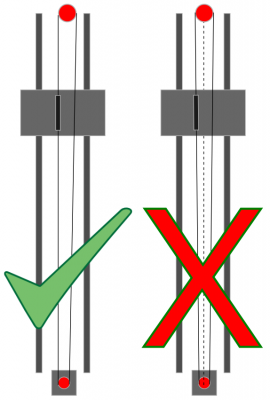

Pruftechnik Group On Twitter Maintancemonday Pulley Misalignment Is Often The Cause Of A Belt Drive Fault And Can Take Various Forms Click Image To Enlarge Find Out More On Pulley Alignment

Pruftechnik Group On Twitter Maintancemonday Pulley Misalignment Is Often The Cause Of A Belt Drive Fault And Can Take Various Forms Click Image To Enlarge Find Out More On Pulley Alignment

Timing Belt Pulley Diameter Charts Pfeifer Industries Timing Belt Pulley Hobby Cnc

Timing Belt Pulley Diameter Charts Pfeifer Industries Timing Belt Pulley Hobby Cnc

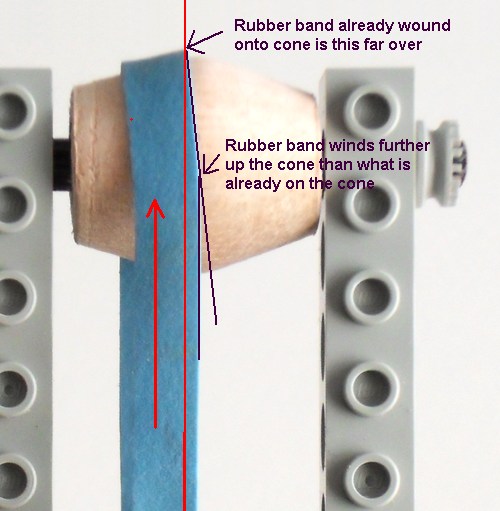

How Crowned Pulleys Keep A Flat Belt Tracking

How Crowned Pulleys Keep A Flat Belt Tracking

Seiffert Industrial Kx 3550 Pulley Pro Belt Alignment Jual Harga Price Indomultimeter Com

Seiffert Industrial Kx 3550 Pulley Pro Belt Alignment Jual Harga Price Indomultimeter Com

How Crowned Pulleys Keep A Flat Belt Tracking

How Crowned Pulleys Keep A Flat Belt Tracking

Groove For Round Belt Pulleys Model Engineer

Groove For Round Belt Pulleys Model Engineer

Technical Informations Of Toothed Pulleys Binder Magnetic

Technical Informations Of Toothed Pulleys Binder Magnetic

Delta Pulley And Idler Dimensions Question

Delta Pulley And Idler Dimensions Question