Thus the tension at the Bottom Side of the belt will be higher than at the upper side of the belt. 7-The rails between the points and the frog.

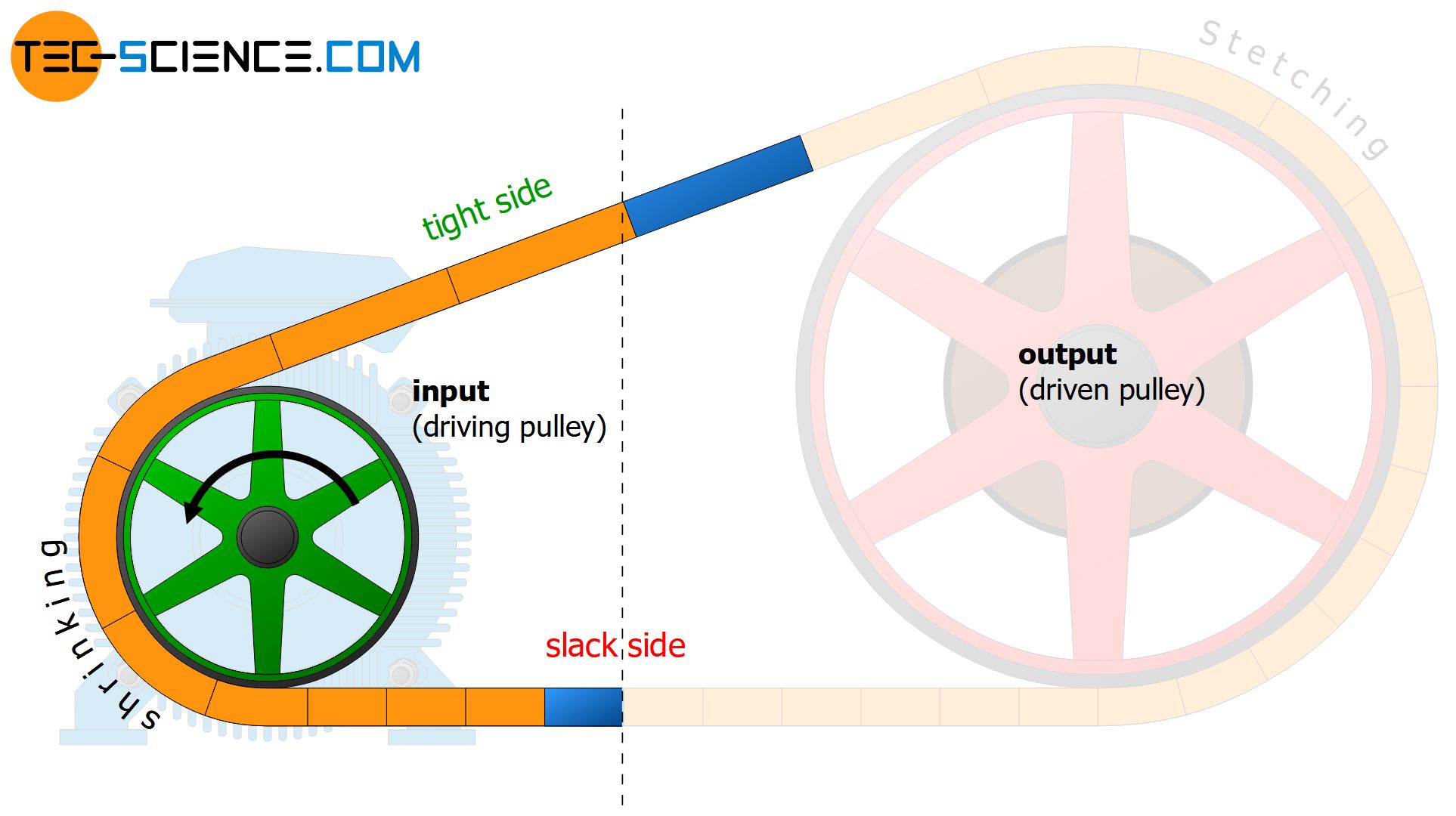

Slippage Of The Belt In Belt Drives Tec Science

Slippage Of The Belt In Belt Drives Tec Science

Any misalignment must be on the slack side.

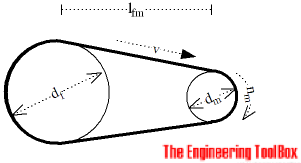

How to engineer a crossed v-belt to change directions. 2 sin 1 r a r b L. Most directional drillers are given a blue well path to follow that is predetermined by engineers and geologists before the drilling commences. A belt drive consists of two parallel shafts and a pulley is mounted on each shaft.

When the superseded drawing will be retained the notation REPLACED WITH CHANGE BY DRAWING Enter the superseding drawing number REV Enter the revision letter of the superseding. θ a 180. Switch are called the stock rails-The movable parts that route the trains one way or the other are called the points or point blades.

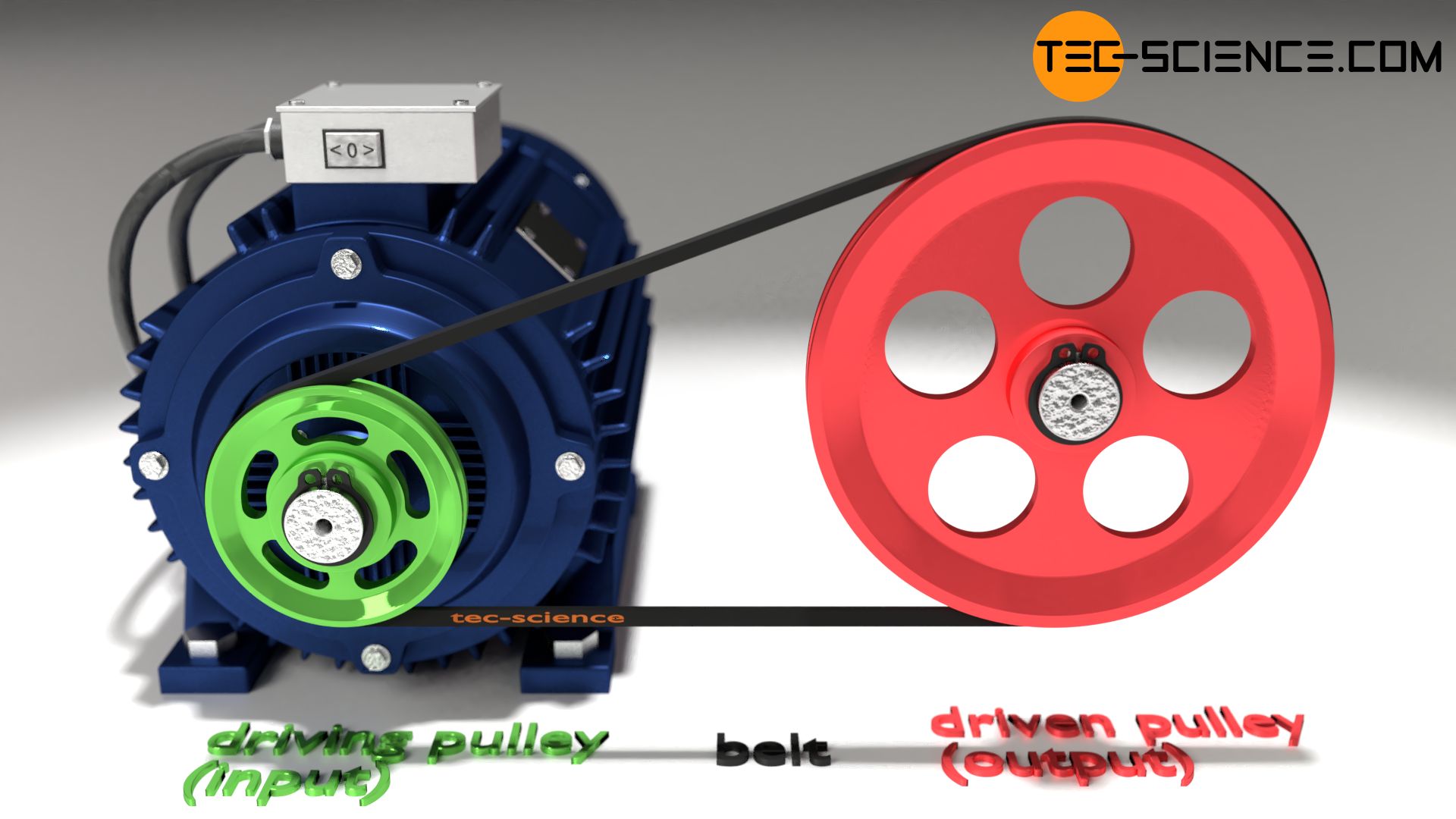

18092010 Quarter Turn Drive. However if one pulley is larger than the other mechanical advantage and velocity. These grooves guide and gain traction on a v-belt.

The most common systems for transmitting power from a drive to a driven shaft are belt. If both pulleys have the same diameter they will rotate at the same speed. V-belts trump flat belts with their small center distances and high reduction ratios.

For synchronous belts it should not exceed 14 deg. This increases load and wear. When the directional driller starts the drilling process periodic surveys are taken with a downhole instrument to provide survey data inclination and azimuth of the well bore.

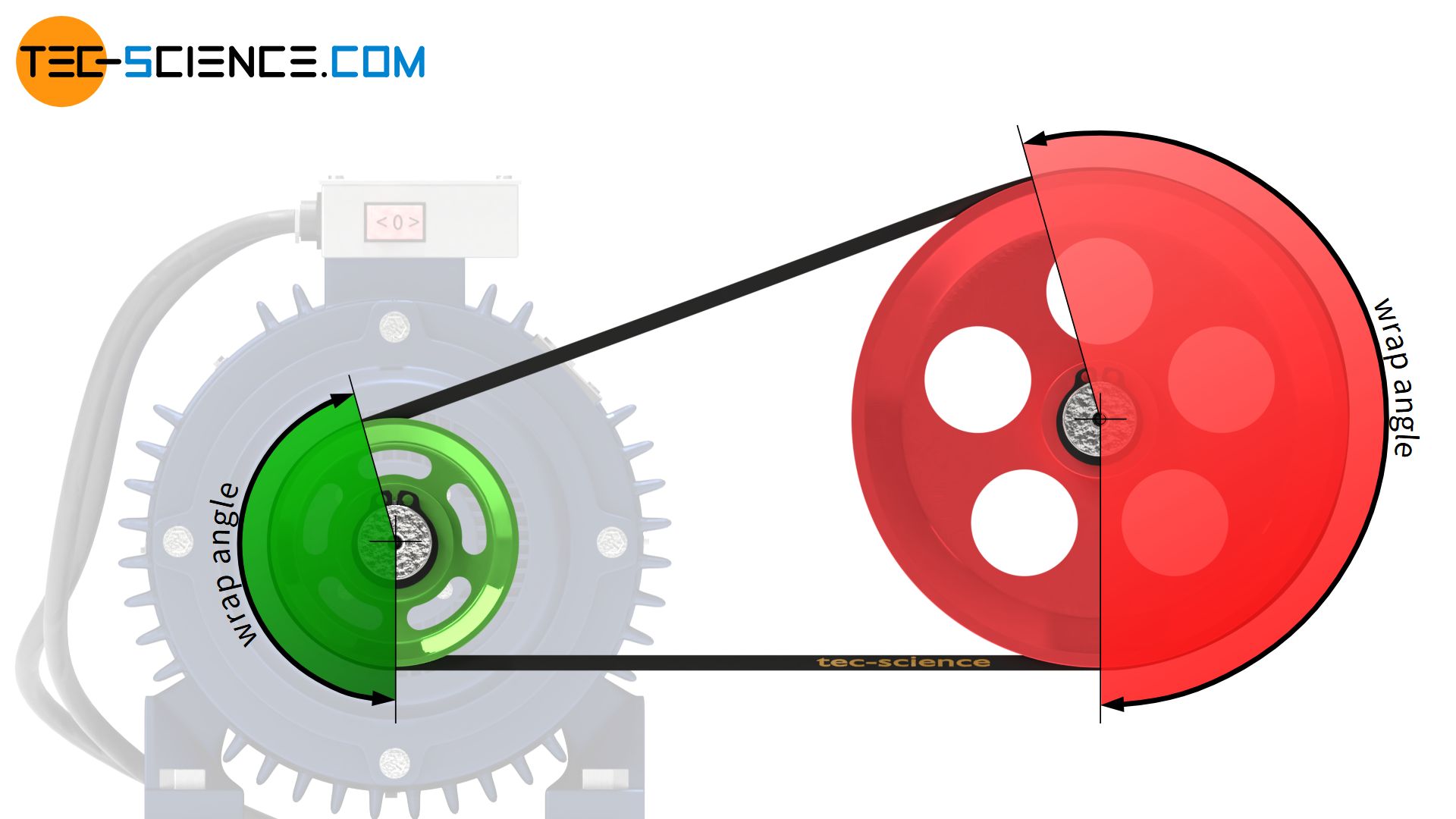

θ b arc of belt contact pulley b. 01042008 V-belt selection its a veritable cinch. In this case the driver pulls the belt from one side and delivers it to the other side.

In these types of belt drive the belt is employing when the two parallel shafts have to rotate in the same direction. Essentially pulleys are gears without teeth that depend on the frictional forces of connecting belts chains ropes or cables to transfer torque. 01092001 Sheave misalignment on V-belt drives should not exceed 12 deg.

Due to creep the speed of driven pulley reduces slightly. Due to these changes in length relative motion occurs between the belt and surface of pulley which is known as creep. L distance between pulley centres.

13072020 Jockey pulley drive. Otherwise the belt will jump and be very short lived. S percentage slip.

Ir my memory is still correct one of the major requirements is that the centerlines of the belt groves on the tension side must be in line and the twist must be on the tension side also. Speed ratio N a N b r b r a 100 s 100. An endless belt runs over the surface of the pulley.

When pulley b is the driver Arc of contact rarb. The belt also tends to wedge into the groove as the load increasesthe greater the load the greater the wedging actionimproving torque transmission and making the V-belt an effective solution needing less width and tension than flat belts. V belt velocity.

Engineering Drawing Practices Drawing Practices. 2 sin 1 r a r b L. When you have eliminated the strongJavaScriptstrong whatever remains must be an empty page.

Here driving shaft and driven shaft rotate in opposite directions. Superseding a Drawing with that of a Different Number b Superseding Old Drawing. 08062019 Contrary to this in crossed belt drive belt proceeds from the top of one pulley to the bottom of other pulley and thus crosses itself in between two pulleys.

Cross or twisted belt drives are used with rotating shafts in parallel and opposite directions. A well-engineered V-belt will have transverse rigidity which means a high level of rigidity across its width so that the tensile cords will transfer the load equally. The twist introduces a sideways torque making the belt align non-uniformly stretch and compress non-uniformly and rub against any stops that prevent it from falling off or be prone to fall off in absence of such stops.

θ b 180. V-belt pulleys are solely used for transmitting power between two parallel axels. Power transmission by belt drive is one of the most common and universally used methods of transmission system when two shafts are parallel up to 10 m to each other as shown in Fig.

17072013 Pulleys and Belts transfer rotating motion from one shaft to another. 07042015 When a belt passes from tight side to slack side a certain portion of the belt contracts and it extends again when the belt passes from slack side to tight side. The accompanying video offers a comprehensive overview of.

At the same time the belt must be highly flexible along its length to reduce heat and bending stresses which in a superior belt is accomplished by parallel alignment of fibers in the rubber compound. It offers higher contact angle so power or torque transmission capacity also increases. The throw bar or tie bar ties the points together and controls their movement from side to side-The crossing in the middle where the rails meet is called the frog.

When the shafts are far apart the lower side of the belt should be the tight side and the upper side must be the slack side. The most notable difference between a v-belt pulley and other types of pulleys round belt flat etc would be the geometry of the groove or grooves located around the circumference of the pulley.

Belt Transmissions Length And Speed Of Belt

Belt Transmissions Length And Speed Of Belt

Difference Between Open Belt Drive And Cross Belt Drive

Belt Tension An Overview Sciencedirect Topics

Belt Tension An Overview Sciencedirect Topics

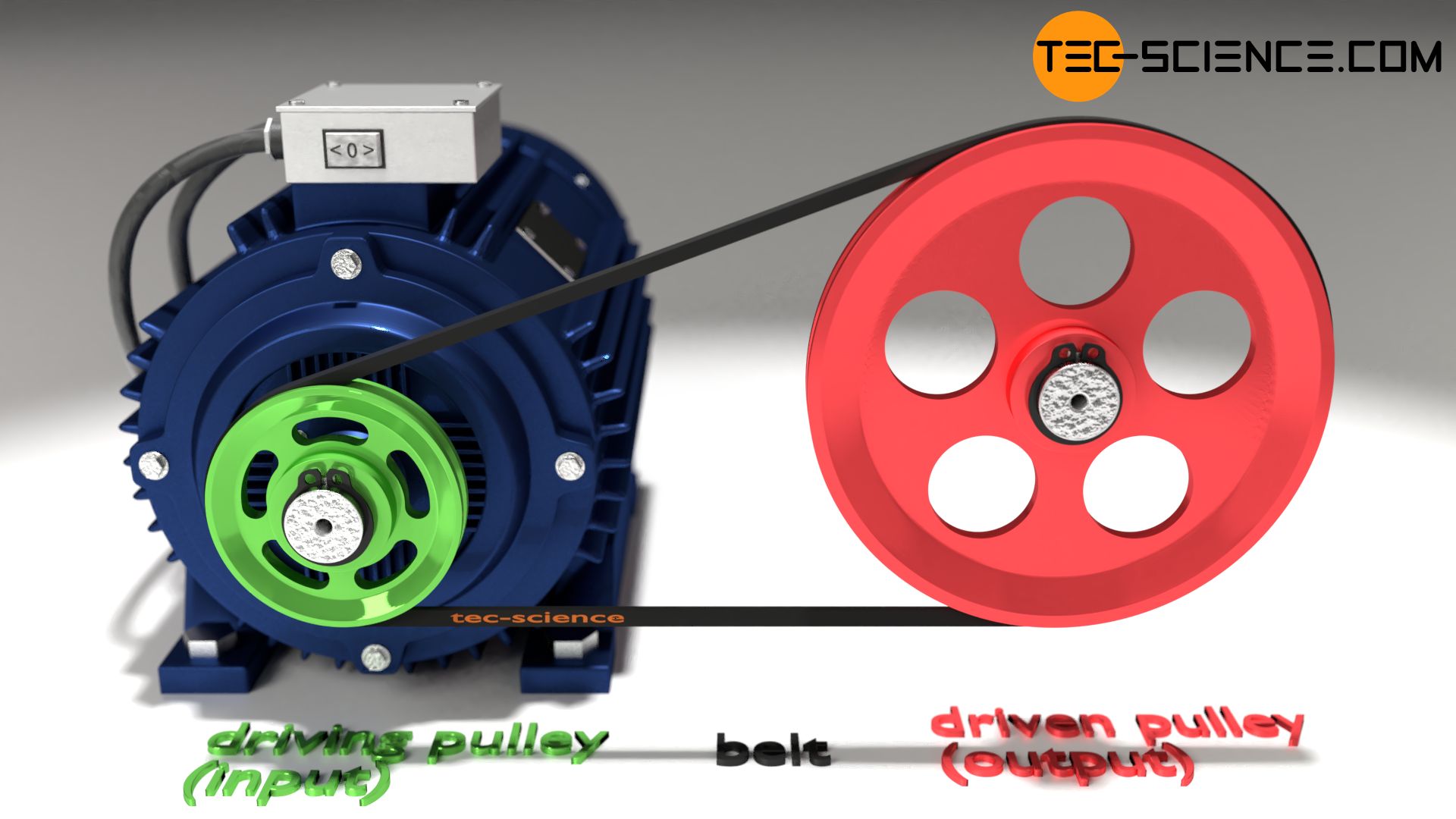

How Does A Belt Drive Work Tec Science

How Does A Belt Drive Work Tec Science

How Does A Belt Drive Work Tec Science

How Does A Belt Drive Work Tec Science

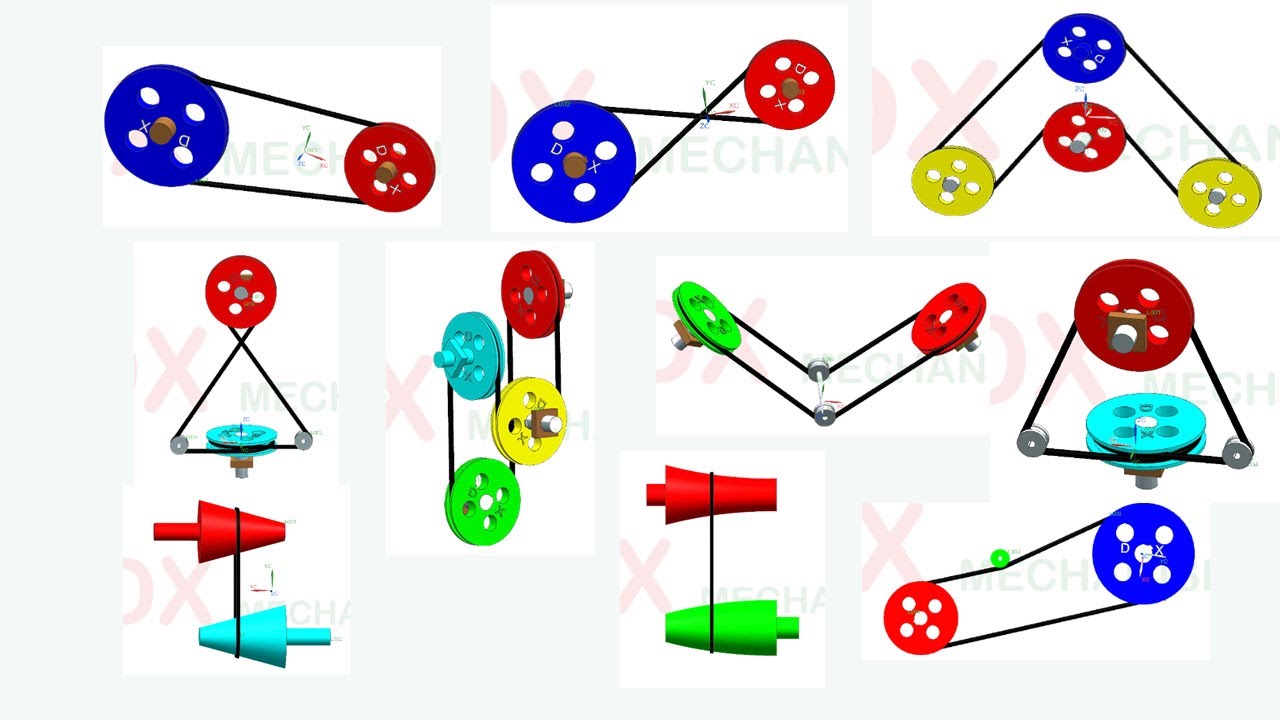

10 Belt And Pulley Mechanism Examples Mechanicalengblog

10 Belt And Pulley Mechanism Examples Mechanicalengblog

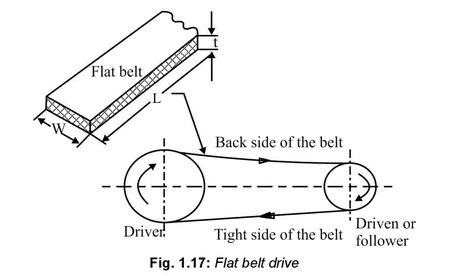

What Is Flat Belt Drive Its Advantages And Disadvantages

What Is Flat Belt Drive Its Advantages And Disadvantages

Diagram 2005 Ford Taurus Sel Serpentine Belt Bypass Belt Taurus Car Club Of America Ford Taurus Forum Taurus Car Taurus Belt

Diagram 2005 Ford Taurus Sel Serpentine Belt Bypass Belt Taurus Car Club Of America Ford Taurus Forum Taurus Car Taurus Belt

10 Belt And Pulley Mechanism Examples Mechanicalengblog

10 Belt And Pulley Mechanism Examples Mechanicalengblog

Mechanical Advantage For Pulley Systems Mechanical Advantage Pulley Survival

Mechanical Advantage For Pulley Systems Mechanical Advantage Pulley Survival