The shaft transmits 20 KW power at 400 rpm. When you tighten the pulley nut you should hang the wrench on the nut and push toward the front of the saw to tighten.

These bushing types include keyed versions for.

Install v belt pulley on shaft. Almost all variations of shaft-to-shaft pulley misalignments result in higher than usual axial vibration. For correct alignment the edge of the non-movable flange lines up with the. 25 35 09 9 75 A steel pulley belonging to the V-belt mechanism will be installed on a hollow shaft by pressing.

Inspect and service take-up rails bearings and shafts. 10 Point V-Belt Installation Check List 1. Shorten center distance and remove old belts.

Do not use crowned pulleys V-Flat drives are for use with wide variable speed belts only not for A or B section type belts. Inspect and clean sheaves. Angle of wrap of belt on pulley is 180 0 and the belt tensions act vertically downwards.

Removing Pulleys from a motor shaft Once you have determined how a pulley is fitted to the motor and you are sure you have unscrewed any grub screws etc the easiest way to remove it is with a gear puller. Multiple V belts with unequal tensions also cause a high axial vibration. Clean the surface of the transmission shaft push the pulley with taper sleeve to the predetermined position on the shaft and check whether the V-belt pulley is aligned.

Install new belts on the pulleys so that the slack sides of all belts are on the same side at either top or bottom of the drive. The ratio of belt tensions 25. Put the other pulley into the belt loop and slip it onto the other shaft bushing loosely installed.

A rotational moment of MD 200000 Nmm will be transmitted from the pulley to the. A belt pulley is keyed to the shaft midway between the supporting bearings kept at 1000 mm apart. V-Belt Drive Installation and Maintenance Manual These instructions must be read thoroughly before installation or operation.

The shaft is made of steel having ultimate tensile. For the fitting of new belts. Install V Pulley onto engine shaft.

The pulley is required to be capable of 20 years operation at full load 300 rpm 2 shifts per day. Drill a dimple in the shaft and just use the set screw. Pulley has 400 mm diameter.

2 See if a a motor or machine shop can mill a keyway in the shaft. Check and correct sheave alignment. The deflection requirements at the keys dicate a larger shaft diameter of 130 mm Dia.

Check Sheave Alignment Sheave alignment should be checked by placing a straight edge or tight cord across the sheave faces so that it touches all four points of contact. DO NOT UNDER ANY CIRCUMSTANCES install belts by prying them onto pulleys by any forcible method. NOTE engine should come with key stock for crankshaft we DO NOT provide this.

Before installation check the pulleys for wear and other foreign material. 28112007 1 Use a fixed bore pulley. The DRIVEN sheave is flat.

Install the nut onto the arbor. Belts should be fitted by hand pressure only. 3 Use a pulley that uses a tapered bushing to mount to the shaft.

Lay belts over sheaves. And aminor shaft diameter of 35. If the technique above doesnt work the method shown in the 2nd drawing on the right should.

Installation Section B V-Flat Drives V-Flat Drives are Hexadrive series pulleys with one movable flange. Worn out pulleys must be replaced to ensure good contact between the pulley and the belt. Install the 1 piece pulley on the arbor and install the key provided.

01082000 Several types of tapered bushings can be used to mount V-belt sheaves and synchronous belt sprockets hereafter called pulleys to drive shafts. Align keyway slot with keystock on engine. Replace worn and damaged sheaves.

Prevent damage to your power steering pump back-plate by properly installing the pulleyInstructions1 Lubricate the pump shaft with an extreme pressure lub. Sometimes the primary frequency is at 2 x rpm but more often it is at 1 x rpm. Tighten 4mm alan hex set screw on pulley to secure.

Whatever you do keep fingers out of. You can apply a wrench to the crankshaft pulley any pulley still driven by a belt or by using the starter to crank the engine for just a fraction of a second. Turn equipment OFF and lock out power source.

Mount one pulley onto the shaft loosely and put the belt on it. Worn out pulleys if not replaced may lead to the following problems -. May need hammer to GENTLY tap to seat fully onto shaft.

The pulley is jacked off of the motor shaft by turning the central bolt of the gear puller using a spanner. Ordinarily a misalignment of more than one-. Oil the screw TB 1008-tb 3030 and thread TB 3525-tb 5050 and screw them into the installation hole but do not screw them tight temporarily.

Link belongs to dimensions are given in the figure. B Exectutive Summary to be finalised Fatigue requiremenst on the shaft alone would permit the use of steel shaft of a minimum 100 Dia to be used. Replace any pulleys with worn chipped or cracked groove surfaces.

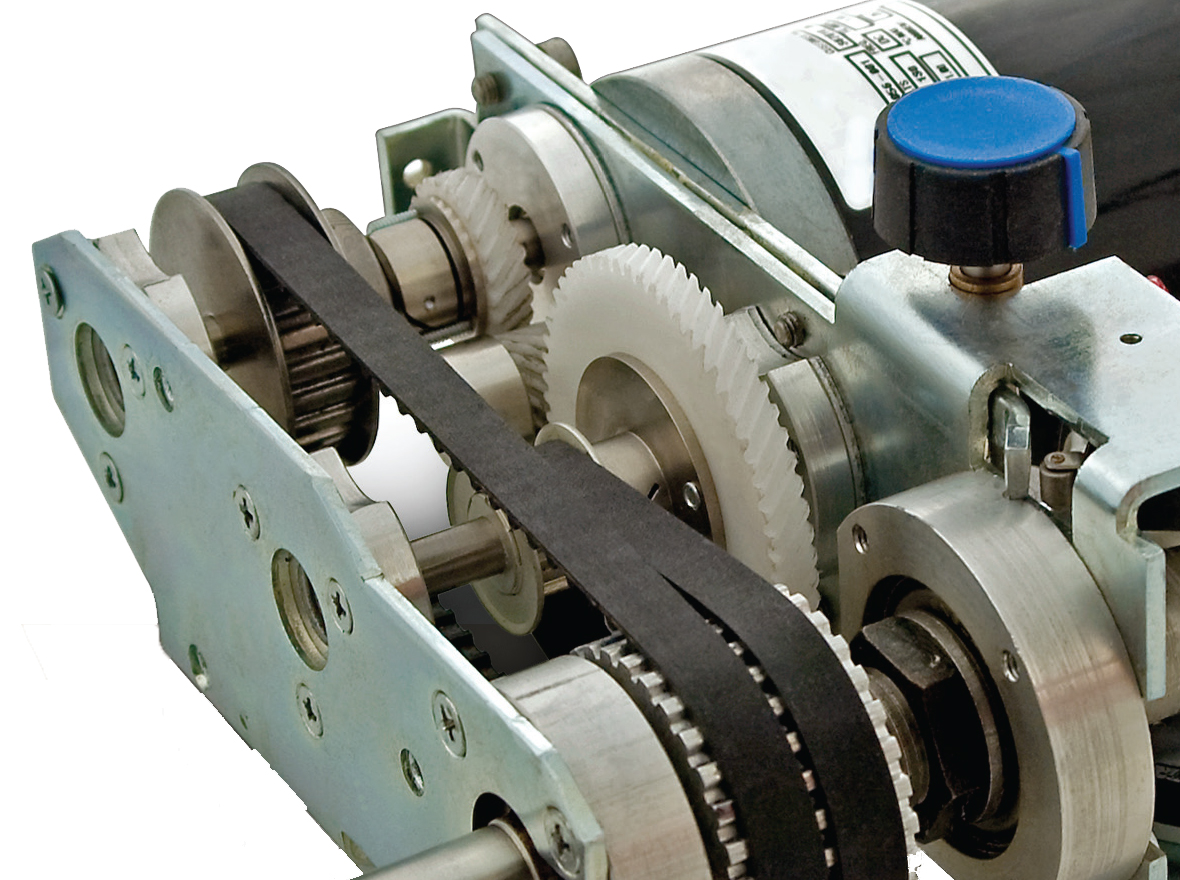

V Belt Pulleys Selection Guide Types Features Applications Engineering360

V Belt Pulleys Selection Guide Types Features Applications Engineering360

Powermaster Powergen 3 8 Alternator Pulley 1131 Alternator Pulley Billet Aluminum

Powermaster Powergen 3 8 Alternator Pulley 1131 Alternator Pulley Billet Aluminum

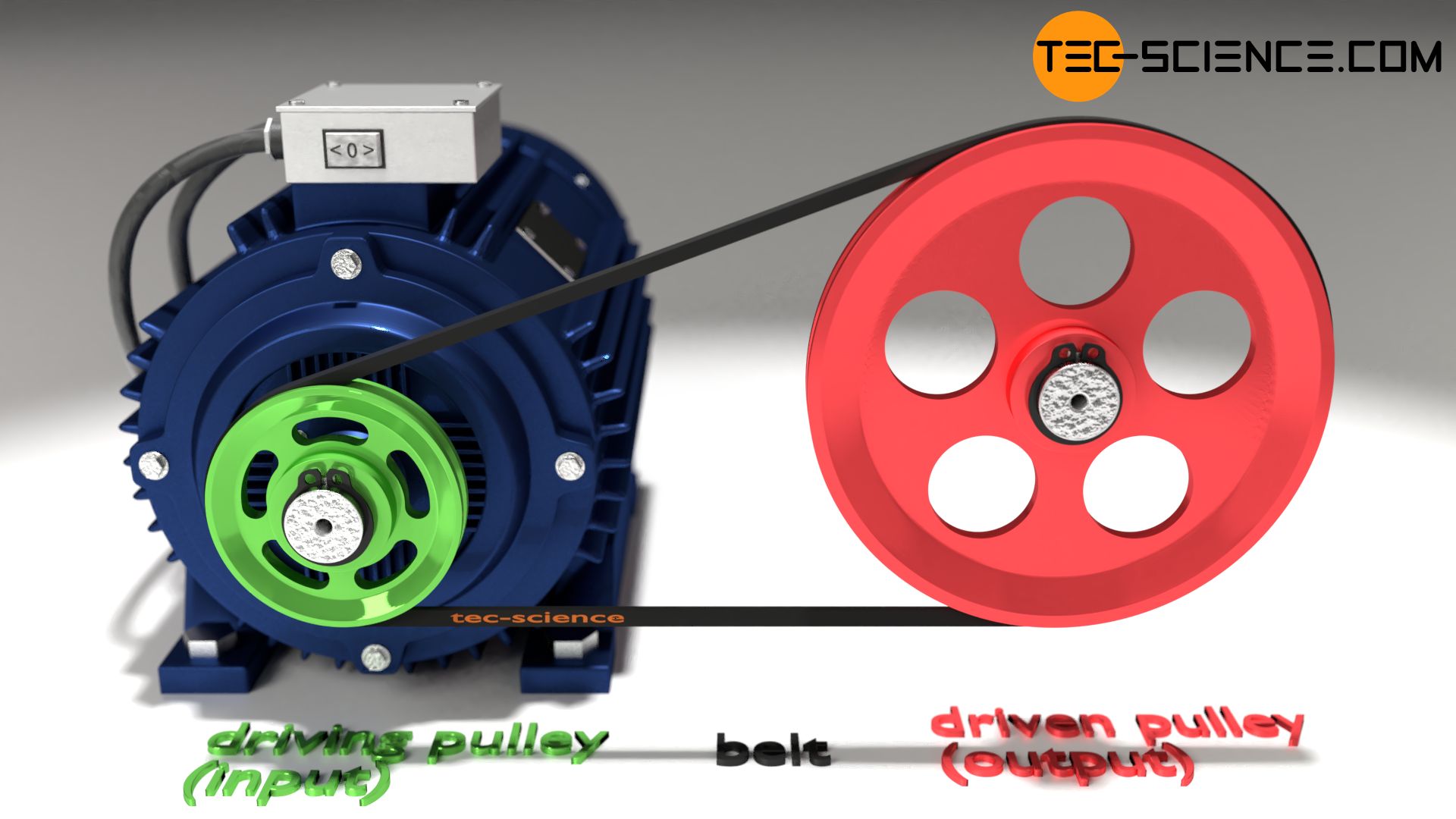

How Does A Belt Drive Work Tec Science

How Does A Belt Drive Work Tec Science

Timing Belts In The Car Play Such A Very Important Role But They Are Rarely Considered Whenever It Is Time For Maintenance And Repairs Timing Belt Belt Pulley

Timing Belts In The Car Play Such A Very Important Role But They Are Rarely Considered Whenever It Is Time For Maintenance And Repairs Timing Belt Belt Pulley

Pdf Dynamics Of Belt Pulley Shaft Systems

Pdf Dynamics Of Belt Pulley Shaft Systems

Belt Pulley Definiton Functions Types Parts Working Studentlesson

Belt Pulley Definiton Functions Types Parts Working Studentlesson