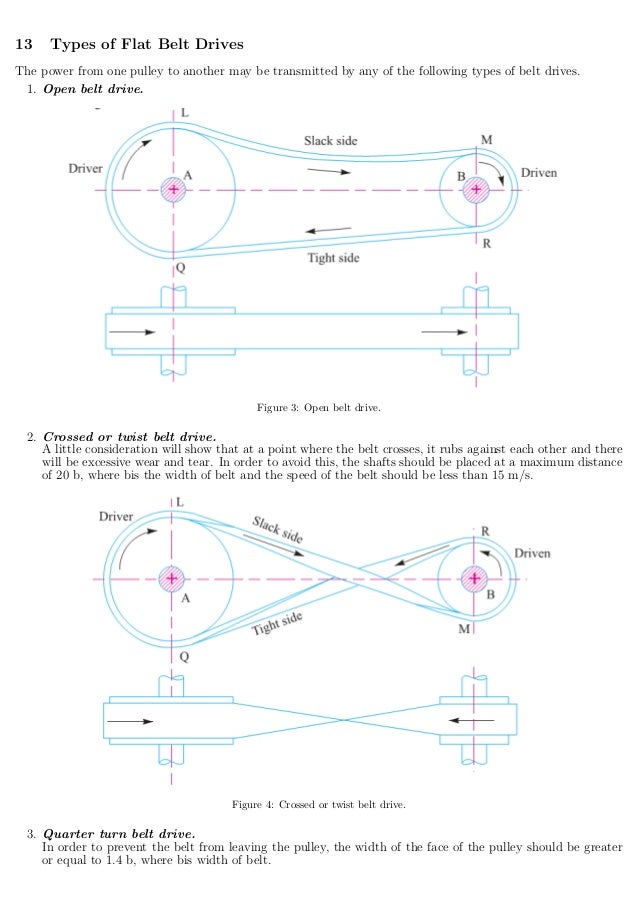

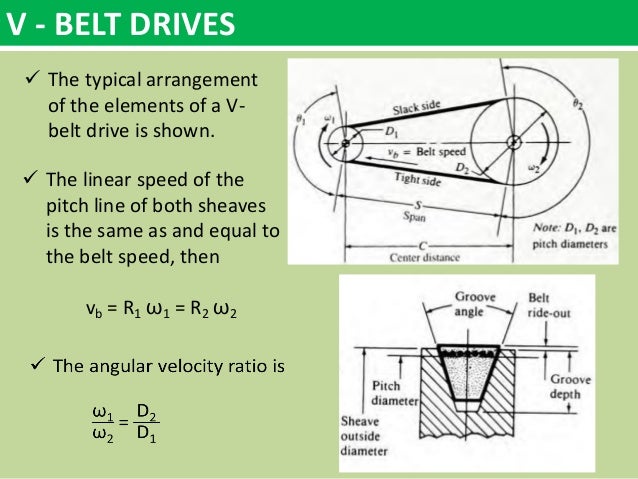

However because belt slip is inevitable actual ratios vary. A4L Section - 12.

Robotic Mechanisms Pulleys And Belts 51045 Robotpark Academy

Broken Belt Unkown Length.

Optimal distance for v-belt. The optimizing process can be initiated using the button Optim. V-belt tensioning can be performed using a tension tester gauge using the procedure in Figure 2. So you need to use proper set of units for inputs to get correct results.

Forcing the belts can cause internal injury to the belts. You take a closer look only to realize that the belt is old and worn and you cant make out a single word on it. For example 3L300 part number indicates 38 top width with 300 outside length.

Distance h d 35 48 Recommended minimum datum pulley diameter d d min 180 280 Weight per meter kgm 0206 0389 Flex rate s-1 f B max 100 Belt speed ms vmax 50 Profile 5V15N 8V25N Datum width b o 15 25 Belt height h 13 23 Recommended minimum outside pulley diameter d a min 191 315 Weight per meter kgm 0204 0603. The numerical prefix indicates the belt top width in one eighth of an inch followed by nominal outside length in inches. V-Belt Length is a measure of required belt length based on the distance between the center of two pulleys and their diameters to effectively transmit the rotating force from one to another.

After seating the belts in the sheave groove and adjusting center distance to take up slack in the belts further increase the tension until only a slight bow on the slack side is apparent while the drive is operating under load. 05022018 Compare this force with the value given in the V-belt tensioning table. Despite their outward similarities each of these belts is designed for a distinct purpose.

However notice the differences in cord materials body compounds cover configurations temperature ranges and application requirements. Shorten the center distance of the drive until the belts can be put on the sheaves without forcing. Incorrect belt tension methods quickly deteriorate the reliability and efficiency of pulley belt driven systems.

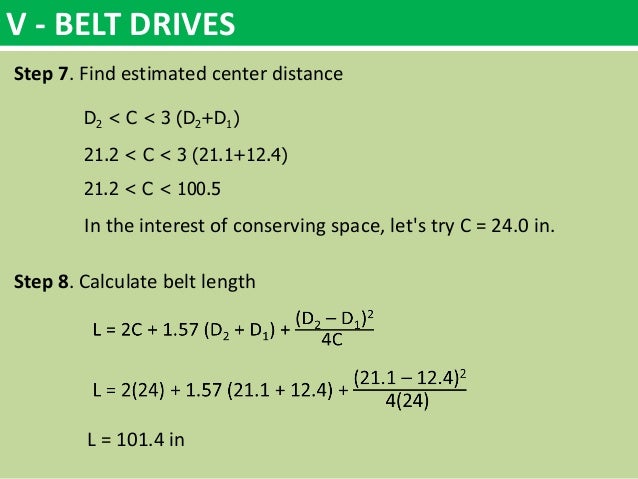

After seating the belts in the groove and adjusting center distance so as to take up slack in the belts further increase the tension until only a slight bow on the slack. The optimizing process 2262 passes through table diameters of the driving pulley for the selected type of belt performs a design of the optimum axis distance calculates additionally all other parameters and tries to find a design with the minimum total weight 212612. The length of the belt can be calculated as.

Kevlar V Belt Sections. For example for a 100 span the deflection would be 10064 or approximately 1. Next if you are building new machinery you will need to consider a few factors when sizing your V-belt.

52 and obtain the center distance factor of 28937 which is larger than the required minimum C MIN 7003. Refer to Tables 1 and 2 for values Tensioning the New V-Belts With the sheaves or idler moved to minimum center distance for belt removal as described above the new belts can be. Youll also need to measure the width and depth to determine which section v belt you have.

Measure the distance from the center of one pulley to the center of the second pulley. Belt Length Calculator Distance Between Pulleys Calculator. They are identified with a 2L 3L 4L or 5L prefix.

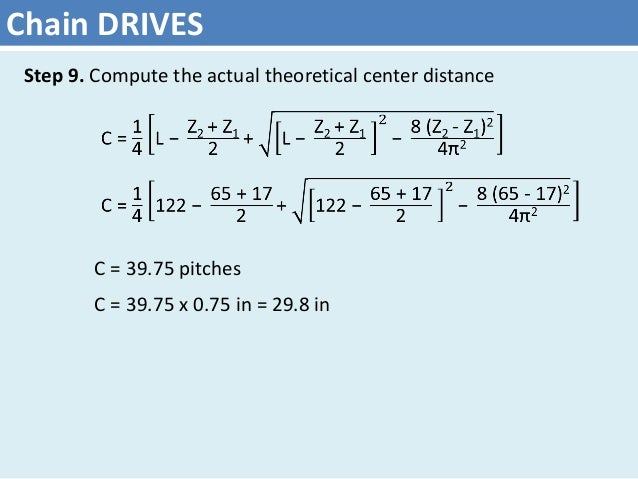

Assuming the pitch of the belt to be 5 mm the actual center distance in mm is 28937 x 5 144685 mm. The unit of the results C and L is the length. Reduce the center distance if there is too much force.

The measurement you need is actually the circumference of the belt which is why you should use a soft measuring tape or other measuring tool. Using these methods you can quickly easily and accurately measure the belt tension and identify if. Each of these belts has a 12-inch top width and 50-inch circumference.

If 3 mm pitch belt is used the center distance factor 28937 has to be multiplied by 3 and a center distance of 86811 mm is obtained. Lb dm π 2 df π 2 2 lfm df - dm2 4 lfm 1 where. Formula to calculate required length of v-belt between two pulleys.

Do not forget to leave your comments and questions about center distance and pitch length calculator for V-belts below. If the speed ratio is less than 1. 01042008 Theoretical speed ratios are stable because slippage is ignored about 5 speed loss.

Have you ever been out in the field or to a customers site only to discover a broken belt. Also keep in mind belts do stretch and unfortunately there is no specific value for how much a belt can stretch. 12112020 Take care about your units.

Force-deflection and sonic testing meters are 2 ways to correct this. Multi-Rib Series V-belt tensioning adjustment can be made using a tension gauge or other type spring scale using the following pro-cedure. You can use MB-Unit Converter tool to obtain correct set of units.

Lb length of belt mm inches df pulley sheave diameter fan mm inches dm pulley sheave diameter motor mm inches π 314. SEE ALL ONLINE CALCULATORS. If there are more than two pulleys on the belt take your measurement using the two pulleys with the longest span of the belt.

Further you will need to also measure the width and depth of the V-belt. If the force is below the recommended value increase the drive center distance to provide greater belt tension. B5L Section - 58.

3L Section - 38. Part number designation for FHP belts are similar to wedge.

Danotes V Belt Drives Introduction

Belt Drives An Overview Sciencedirect Topics

Belt Drives An Overview Sciencedirect Topics

Belt Length Calculator Distance Between Pulleys Calculator

Belt Length Calculator Distance Between Pulleys Calculator

Belt Length Calculator Distance Between Pulleys Calculator

Belt Length Calculator Distance Between Pulleys Calculator

Danotes V Belt Drives Introduction

Pulley Belt Calculations The Engineering Mindset

Pulley Belt Calculations The Engineering Mindset

Optimal Drive Configuration For Plastic Modular Belts Habasit Expert Blog

What Is The Formula For Finding The Centre To Centre Distance Between Two Pulleys In A V Belt Drive Quora

What Is The Formula For Finding The Centre To Centre Distance Between Two Pulleys In A V Belt Drive Quora

Pulley Belt Calculations The Engineering Mindset

Pulley Belt Calculations The Engineering Mindset