14 0250 6A 09 90 70 45 V-S 516. BEARING TEMPERATURE DUE TO BELT TENSION 175.

Belt Tensioning Tips A Technical Tip From Gates Mechanexpert

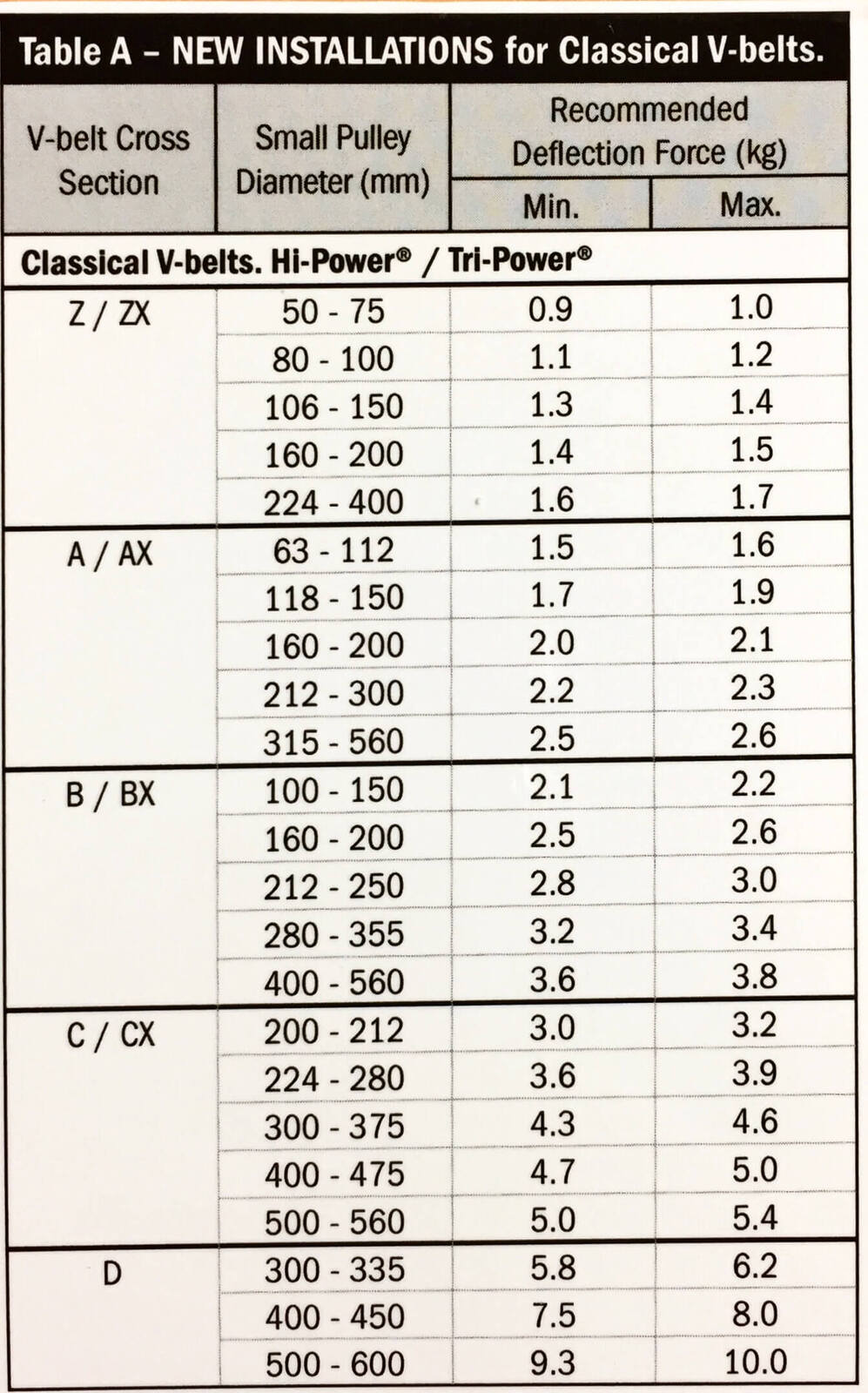

Standard V-Belt Tensioning Deflection Force Table Belt Cross-Section A AX B BX C CX D E 3V 3VX.

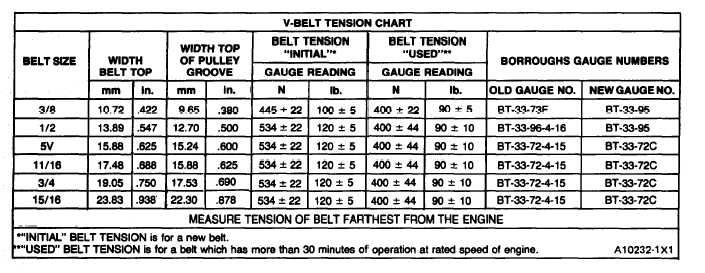

V belt tension chart. Timing Belt And Multi V Kits. Ment between belts and pulleys Tension the belts to the 125x setting forces from the table. Check tension frequently during the first 24 hours of operation.

Tst lb 15 θ θ K 25 K b c d g V W N V P 1 60 09 10 3 2 where. 143-147 Calculating the Axial LoadShaft Load. DESIGN SUPPORT Belt Tension for Optibelt V-Belts and Kraftbands.

How to increase Belt Life Keep sheaves and belts clean. V-Belts SPCP Aramid tensile cords provide superior service on high impact shock-loaded drives. Check after jog start or 1-3 minutes of operation at 8 hours 24 hours.

Pd design power as determined in Section 311 W belt weight per foot of length lb. Quattro PLUS belts. Belts that are too loose will slip causing excessive belt and sheave wear.

Timing Belt And Multi V Kits. A well-established rule of thumb is that the best tension for a v-belt drive is the LEASTtension at which the drive will not slip under peak load. AP BP CP 5VP 8VP SPBP 12 516 2132 1332 78 1732 78 58 1 16mm 22mm 3564 13mm 18mm Super HC.

Over tensioning shortens belt and bearing life. Never use belt dressing to correct slipping belts. Maintain Proper Belt Tension Maintaining correct tension is the most important rule of V-belt care.

Ideal tension is the lowest tension at which the belt will not slip under peak load conditions. CHART Single V-Belts Predator. Check tension frequently during the first 24 hours of operation.

Determine the belt static tension T st by the following formula. You save money and increase drive life. 91107 for Standard Part No.

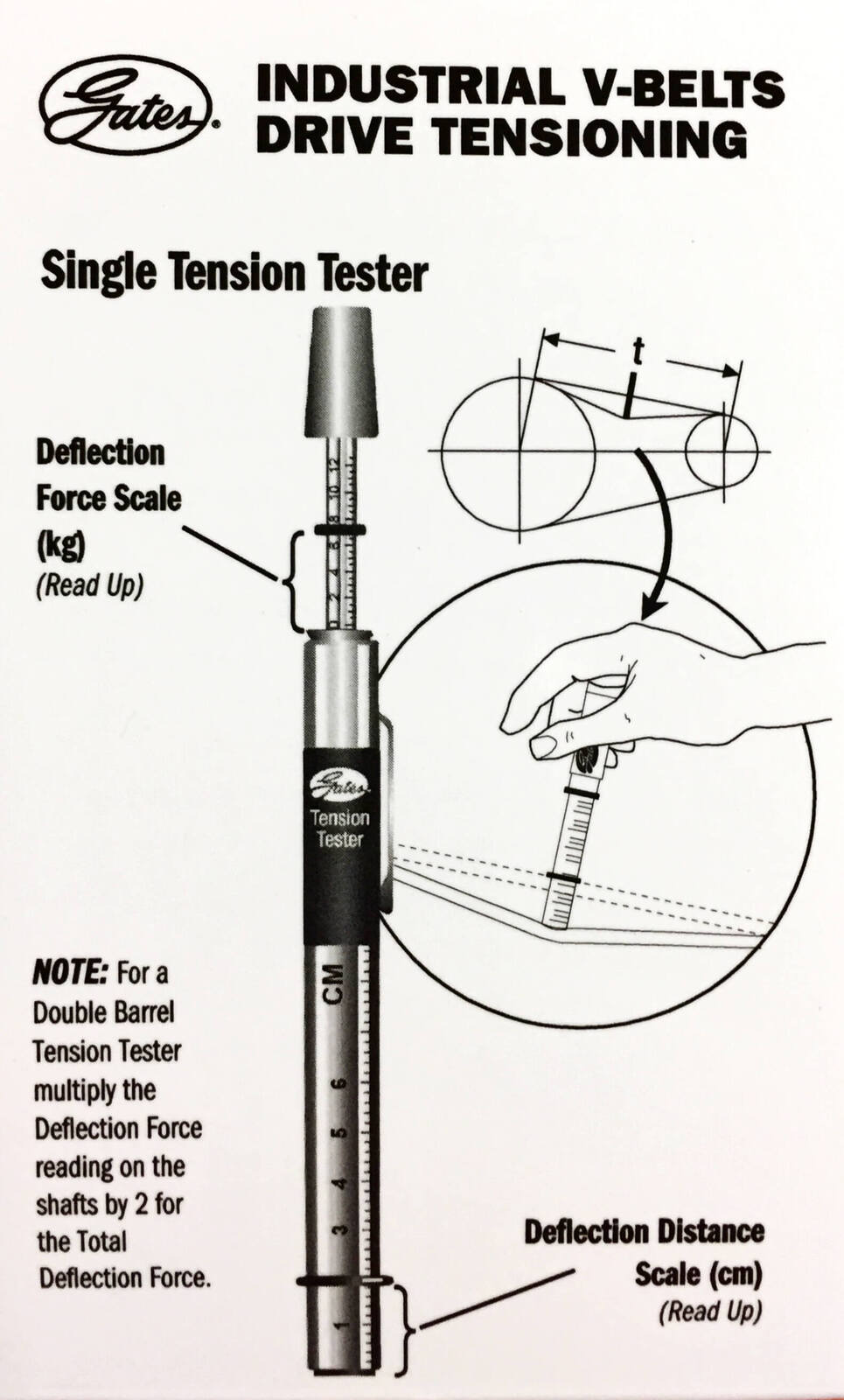

Tension Gauge Part No. A joined V-belt increases lateral ri-gidity to reduce belt whip and main-tain stability under shock loads. 05022018 Designed for the tension testing of a drive with two or more belts this pocket-sized tool measures V-belts from 10 to 170 and up to 35 pounds of tension.

HIGHER BELT TENSION 5 slip belt slip starts min tension after normal loss reccommended installation tension 2x higher belt tension 25x higher belt tension 3x tension. It will give the belts 50 to 100 longer life. SECTION 10 BELT TENSIONING 101 What Is Proper Installation Tension One of the benefits of small synchronous belt drives is lower belt pre-tensioning in comparison to comparable V-belt drives but proper installation tension is still important in achieving the.

Never let belts run against belt guards or other obstructions. V belt speed fpm 12 Driver RPM Driver Pitch Diameter in. 148 Technical Tools.

17062021 3208 INDUSTRIAL ENGINE ATTACHMENTS Belt Tension Chart 3208 INDUSTRIAL ENGINE ATTACHMENTS V-Belt Tension Chart 3208 INDUSTRIAL ENGINE ATTACHMENTS Air. See Table 2 below for typical values. When you install a new set of belts use the gauge to establish correct tension.

Purchase Skf Belt Tension Meter Up To 73 Off. Run the drive under load for 15-20 minutes. Measure belt span and measure the force required to deflect any one of the belts 164 for every inch of span length.

Ideal tension is the lowest tension at which the belt will not slip under peak load conditions. Pm Ltp Um M Ea P 4 X 3 V02 2009 06 18. The payoff is maximum belt life reduced downtime and uninterrupted equipment service.

Always use a belt tension gauge that indicates static tension such as the Gates Krikit. Use large diameter sheaves and fewer belts. Gates Belt Number And Identification Chart Resources N Technologies.

Also notice for V-belts the deflection forces vary from the initial run-in values which are greater reflecting higher run-in tensioning to the normal values for after the run-in period. Dayco Recommended Tensioning Levels Belt Size New Belt SAE Dayco Series Installation Tension RETENSION Amount After 3-5 minute Run-in Used Belt Tension Measured after belt is allowed to cool IN Metric Dayco Lbs. BELT TENSION CHECKER TENSIONING V-BELT DRIVES WITH A BROWNING TENSION CHECKER General rules of tensioning.

09102017 V-Belt Tension Gauge Proper tension is the key to long efficient trouble-free belt operation. Tension ranges above are for drives requiring single belts. Abrasive dust rust oil and acids reduce service life.

Apply Tension A-7 A-8 All v-belt drives must operate under proper tension to produce the wedging action of the belt against the groove sidewall. Then to maintain performance re-check belt tension after 24-48 hours. Stop the drive check tension.

15072020 Powerful Car Alternator Bearing Design. It also simplifies installation and tensioning compared with multiple single belts. Check after jog start or 1-3 minutes of operation at 8 hours 24 hours 100 hours and periodically thereafter are recommended.

Belt Tension Checker See Form 5453 for more detail. Reset to the basic value standard V and wedge belts if necessary. Give drives elbow room.

91132 for Micro-V to determine proper tension from the Installation Chart. Measure the span length t as shown in the sketch above. Most v-belt problems are due to improper tensioning.

Figure 7 Bending stress red area is evenly distributed in a well-engineered notched V-belt while the tensile cord between red and yellow bands remains.

V Belt Tension Gauge V Belt Tension Measuring Tool

V Belt Tension Gauge V Belt Tension Measuring Tool

Hi Wise Products Hi Ensuring Proper Fan Belt Tension

Hi Wise Products Hi Ensuring Proper Fan Belt Tension

Gates Pocket V Belt Tension Guide

Gates Pocket V Belt Tension Guide

Gates Pocket V Belt Tension Guide

Gates Pocket V Belt Tension Guide

Belt Tensioning Tips A Technical Tip From Gates Mechanexpert

How To Tension A V Belt How Not To Ibt Industrial Solutions Ibt Industrial Solutions

How To Tension A V Belt How Not To Ibt Industrial Solutions Ibt Industrial Solutions

Belt Tension Cr4 Discussion Thread

How To Tension A V Belt How Not To Ibt Industrial Solutions Ibt Industrial Solutions

How To Tension A V Belt How Not To Ibt Industrial Solutions Ibt Industrial Solutions