Width Same as 5L. 601 to 1200 40.

What Effect Does The Pulley Diameter Have On The Belt Elasticbelt

What Effect Does The Pulley Diameter Have On The Belt Elasticbelt

V-Belt Sheave Groove Dimensions Belt Section Outside Diameter Range m -025.

Smallest sheave diameter for b size v belt. V m fpm Belt speed. Selection of Belt Size Using the given center distance and the size of the large and small sheaves selected calculate the belt length. Was your belt touching the center of the pulley.

A S -015 Se 3V 3VX Less than 350 36350 340 0 406 094344 -000 350 to 600 38. 5V 5VX Less than 1000 38600 590 0 688 125 1000 to 1600 40. Standard Groove Sheave Widths.

Center Distance and Belt Length The minimum pulley diameters recommended for standard V-belts are shown in Table 3. Belts use the same system of size and length designation as individual belts. Notches reduce bending stress allow-ing the belt to wrap more easily around small diameter pulleys and allowing better heat dissipation.

You were also losing a significant amount of power so no wonder you want a replacement. Despite their outward similarities each of these belts is designed for a distinct purpose. The datum diameter however is slightly less than the outer diameter.

Classical V-Belts 03 Minimum Pulley Diameter Table 3. Bore Solid Sheave Pulley with 2-14. 10 8V 5300 TB 1 B 34 TB 10 Number of Grooves 1 Number of Grooves 8V Belt Cross Section B Belt Cross Section 5300 5300.

18112013 Below are the minimum pulley sizes for both V-belt sheaves and Synchronous sprockets. 8V Less than 1600 38. V belt Design HP.

500 -000 Over 1600 42. Then you were probably ripping through belts more often than youd like 4. Outside Diameter 34 34.

B Section V-Belts - B Section V Belt Sizes. Cast Iron 2 Grooves Bore. Belts Available in A B C and D sections.

For this purpose the following equation is used. Center Distance and Belt Length The relation between center distance and length is given by the following formula. Inch Solid Sheave Pulley 2694 26.

Bg 005 hg Min. A Belt constant obtain from mfg c Belt constant obtain from mfg e Belt constant obtain from mfg D 1 Small sheave pitch diemeter. V and Flat Belt Design and Engineering Data.

Belts Available in 3V 3VX 5V 5VX and 8V sections. Bend around small sheaves. VXB Brand 2BK23 34.

However notice the differences in cord materials body compounds cover configurations temperature ranges and application requirements. V-Belt Sheaves BB Manufacturing. Notched or Cogged V-Belts All of the V-belt types noted above are typically available from manufactur-ers in notched or cogged versions.

Each of these belts has a 12-inch top width and 50-inch circumference. The following table defiens industry standard V-Belt sheave grooves. OD Hex Set Screws for V-Belts Size 4L 5L 2BK23-34.

It is still important however to check with the motor or gearbox manufacturers to ensure that these small pulley sizes do not result in excessive shaft load or fall below any NEMA National Electric Motor Association standards which could prove to be detrimental to the drive. Minimum Pulley Diameter in mm Figure 3. As strong as conventional v-belts but with smaller widths.

B Section Wrapped V-Belts are made of resistant fabric low-stretch tension member specially developed high grade elastomers high performance long service life uniform belt gemometry. The width ranges from 12. K d Small diameter factor estimate or manufacture tables for given velocity ratios.

Classic A Section V-Belt. In terms of sheave dimensions the pitch diameter is now equal to the outer diameter for most standard sheaves. If both are true then your belt will hit around the middle of the groove.

This is important when calculating the length of a belt because the datum length which is the norm for standard V-belt. And lengths from 16. Pin Diameter matches your belt and Overpin Diameter is smaller than Outside Diameter.

C Center Distance D Outer Diameter of Large Sheave d Outer Diameter of Small Sheave Belt Size 2C 157 Dd D-d2 4C. Width Same as 4L Classic B Section V-Belt. 13 rows For example on a flat belt drive on a 207TR40 Class 1 Service 5 HP 14 RPM centered.

A v-belt for light loads and small engines. These are used in many industries such as industrial agricultural material handling HVAC and much more. Belts Available in CP 3VP 5VP and 8VP sections.

A v-belt with a hexagonal cross-section which can gain traction on pulleys placed inside or outside the belt drive. 01112017 For most belts and sheaves the dimensions formerly referred to as pitch length belts and pitch diameter sheaves are now referred to as datum length and datum diameter.

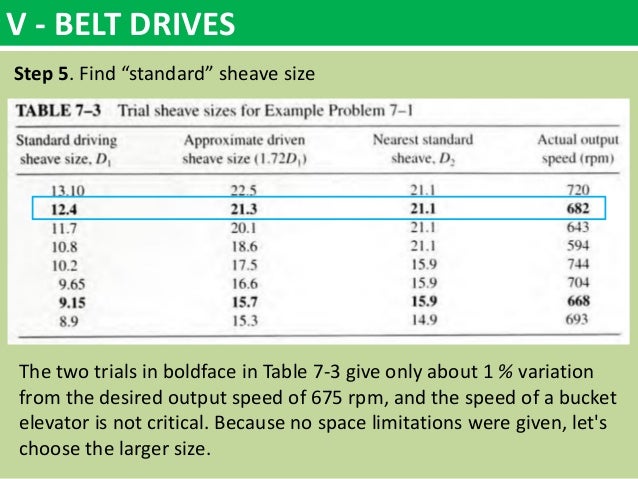

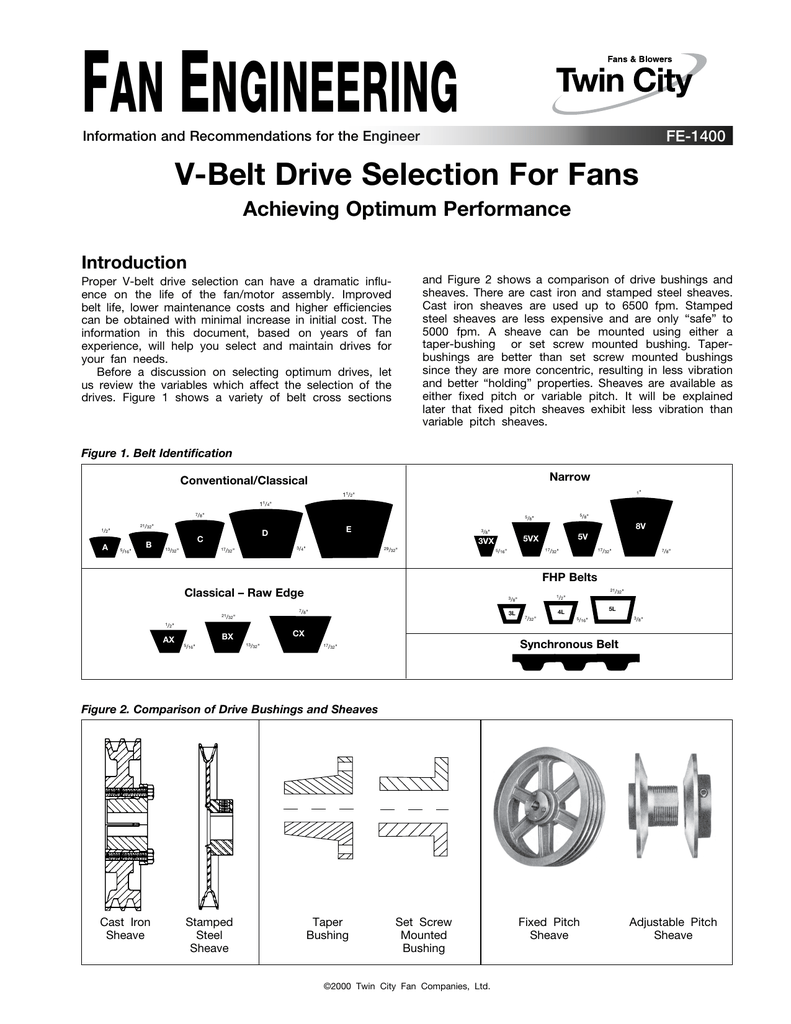

V Belt Drive Selection For Fans Fe 1400 Manualzz

V Belt Drive Selection For Fans Fe 1400 Manualzz

Gates Belts Hoses And Applications Minimum Pulley Diameters How Small Is Too Small

Gates Belts Hoses And Applications Minimum Pulley Diameters How Small Is Too Small

Pulley Belt Calculations The Engineering Mindset

Pulley Belt Calculations The Engineering Mindset

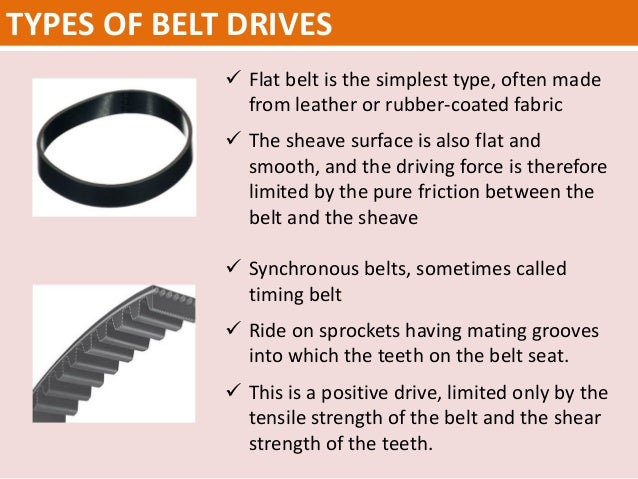

V Belt Pulleys Selection Guide Types Features Applications Engineering360

V Belt Pulleys Selection Guide Types Features Applications Engineering360

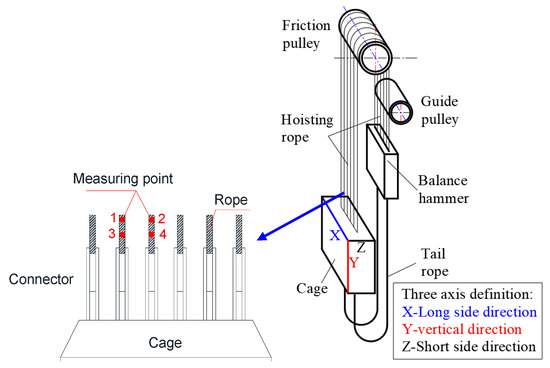

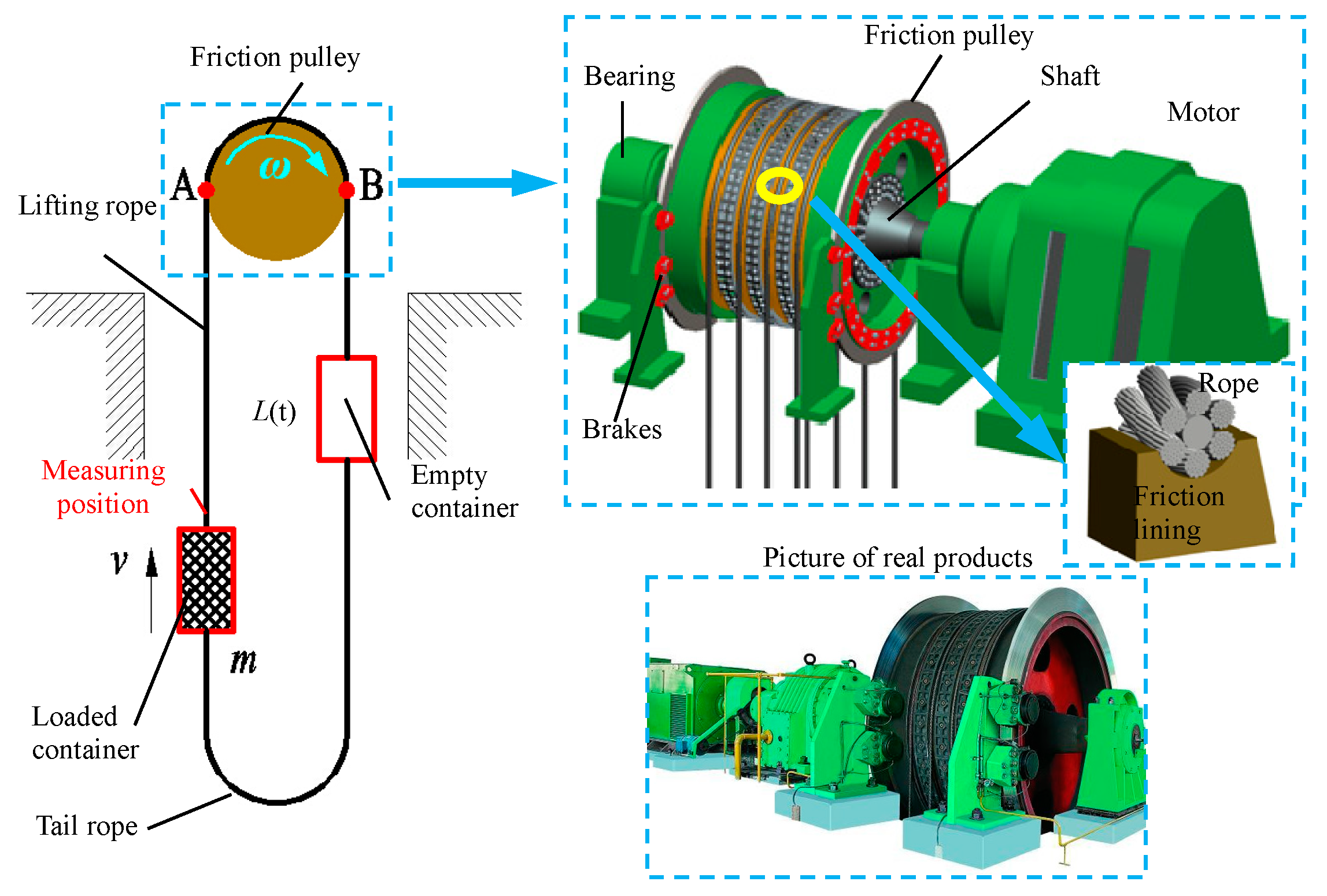

Applied Sciences Free Full Text A New Transmission Theory Of Global Dynamic Wrap Angle For Friction Hoist Combining Suspended And Wrapped Wire Rope Html

Applied Sciences Free Full Text A New Transmission Theory Of Global Dynamic Wrap Angle For Friction Hoist Combining Suspended And Wrapped Wire Rope Html

Pin On Working Smart On The Farm

Pin On Working Smart On The Farm

Step Cone Pulley Design Optimization

Correctly Sizing A Pump Pulley Sheave All Applications All Pumps

Correctly Sizing A Pump Pulley Sheave All Applications All Pumps

Applied Sciences Free Full Text A New Transmission Theory Of Global Dynamic Wrap Angle For Friction Hoist Combining Suspended And Wrapped Wire Rope Html

Applied Sciences Free Full Text A New Transmission Theory Of Global Dynamic Wrap Angle For Friction Hoist Combining Suspended And Wrapped Wire Rope Html

How To Choose A Pulley That Fits Your V Belt

How To Choose A Pulley That Fits Your V Belt

Step Cone Pulley Design Optimization