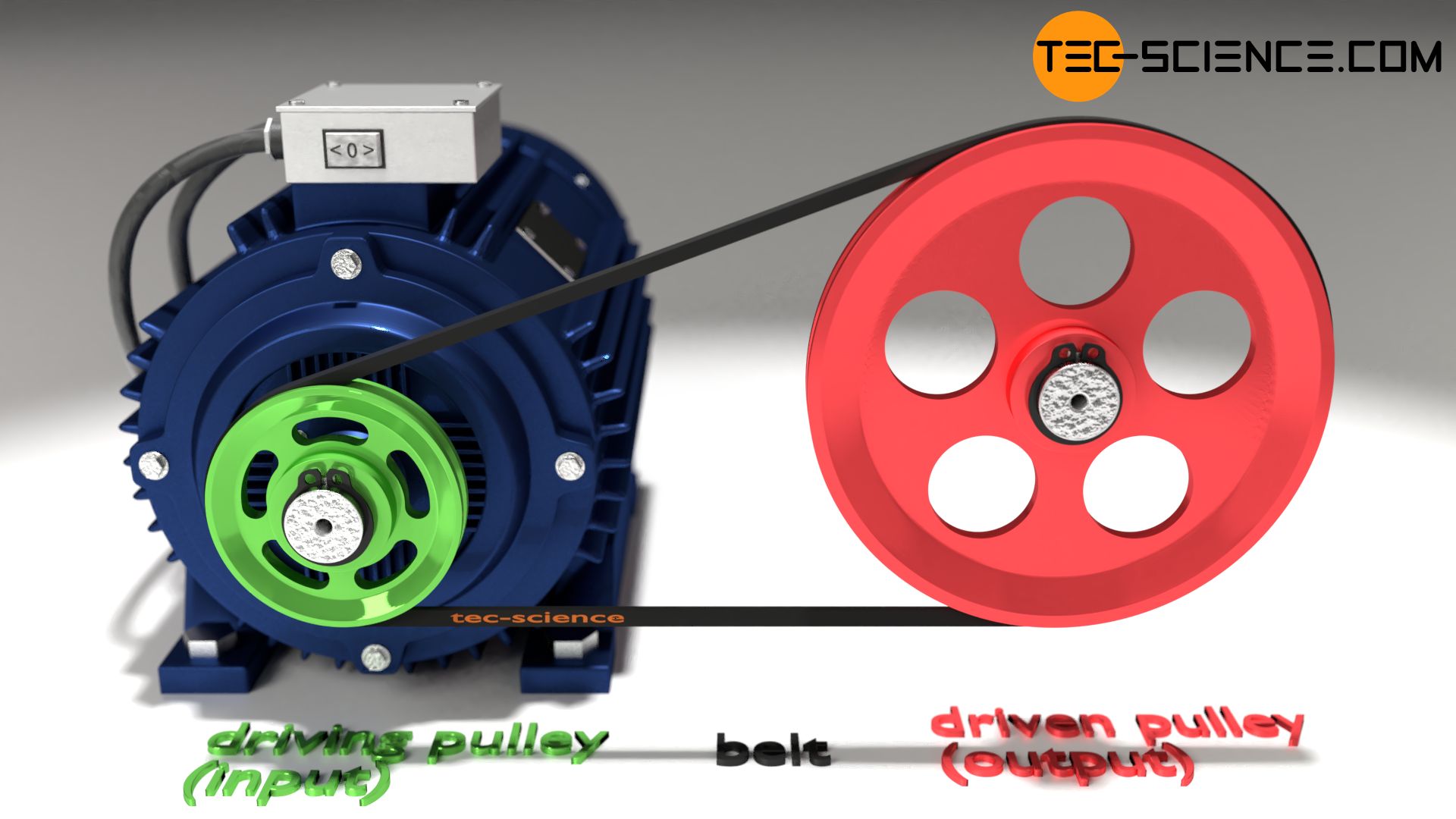

The following parameters are important when selecting v-belt pulleys. Power transmitted between a belt and a pulley is expressed as the product of difference of tension and belt velocity P T 1 - T 2 v where T 1 and T 2 are tensions in the tight side and slack side of the belt respectively.

Tb Wood S 7 8 Fixed Bore Standard V Belt Pulley For V Belt Section 4l 5l A Ax B Bx Bk3678 1 Each Amazon Com Industrial Scientific

Tb Wood S 7 8 Fixed Bore Standard V Belt Pulley For V Belt Section 4l 5l A Ax B Bx Bk3678 1 Each Amazon Com Industrial Scientific

Different brands as well as different pulley types have different ways that they may display these numbers.

How to select v belt and pulley. A joined V-belt increases lateral ri-gidity to reduce belt whip and main-. Select the appropriate belt for the design torque. RPM Belt Length Speed Animated Diagrams.

Fortunately measuring a pulley belt size is easy to do. For example if your small pulley is 80mm diameter and spins at 1000 RPM and you need to find the second pulley size to spin it at 400 RPM Enter Pulley1. SPZ-Z-3V SPA-A SPB-B-5V SPC-C TOLERANCE S Balancing our pbt pulleys are statically balanced according to iSo.

If you know any 3 values Pulley sizes or RPM and need to calculate the 4th enter the 3 known values and hit Calculate to find the missing value. After youve narrowed down your options to pulleys that work with your belt try to choose a pulley that fits one of the following attribute s. If we need to calculate the distance between the centres of the two pulleys then we can use the following calculations to approximate this.

V-belt Section or Timing belt Pitch Dia type of pulley - Select classical v-belt section or wedge belt section or narrow v-belt section or banded v-belt section or timing belts Pitch size of belts to be driven on pully. Pin Diameter is larger than your belt. Belt profile or the style and sizes of the belt being integrated.

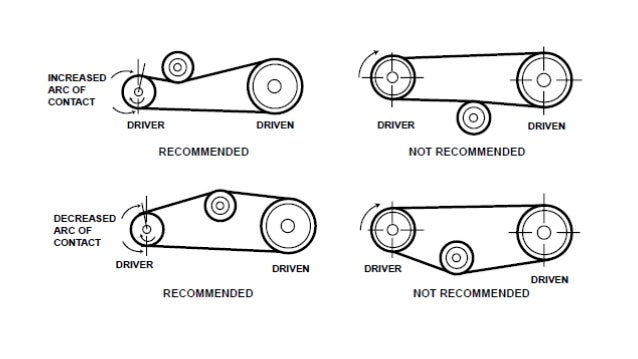

24082012 Align shafts and pulleys to prevent belt-tracking forces and belt edge wear. CONVEYOR PULLEY SELECTION GUIDE PROPER SELECTION OF A CONVEYOR PULLEY When selecting a pulley for a belt conveyor application specifications will be determined by addressing the following steps. As you can see there are many factors to consider before choosing the right V-belt for the job.

Power transmitted between a belt and a pulley is expressed as the product of difference of tension and belt velocity P T1 -T2 v where T1 and T2 are tensions in the tight side and slack side of the belt respectively. Joined V-Belts For applications with vibrating or pul-sating loads especially with long cen-ter distances joined V-belts may be the answer. Belt-and-pulley systems are.

The pt pulleys are not balanced as they do not have a finished bores. SIT V-Pulleys - production range dw mm Tolerance of pitch diameter dw mm Eccentricity tolerance relevant to. A joined V-belt is in essence a number of single V-belts joined togeth-er with a continuous tie-band across the back see Figure 8.

This will guarantee your belt will not be riding at the top of your pulley because a bigger pin means a larger belt fit into the groove. Select the appropriate belt material for the environment temperature chemical cleaning agents oils and weather. Heavy loads and often harsh conditions.

07062019 For a belt drive system the motor torque required during constant velocity is simply the total axial force F a on the belt multiplied by the radius r 1 of the drive pulley. How To Identify a V-Belt Pulley The easiest way to identify a v-belt pulley is by finding the part number or identification components on the pulley its self. If you do choose 3mm pitch pulleys be sure to get 3mm pitch belts as well.

V-groove pulleys suitable for use with the following belts. 01042008 Determine the ratio of your drive application based on the ratio formula and find the closest value in the drive selection tables for your selected belt. Center diameter is the distance or distances between the shafts of the pulleys in the transmission.

26052019 Calculate distance between pulleys. A finer pitch is preferable for the type of movement we do and the belts are cheaper but if you find the 2mm belts or pulleys are out of stock you can go to 3mm pitch without any significant downsides. T c torque required during constant velocity Nm F a total axial force N r 1 radius of drive pulley mm η efficiency of belt drive system.

STEP 1 The Face Length of the Conveyor Pulley STEP 2 The Anticipated Belt Tension of the Conveyor System. Dont crimp belts beyond the smallest recommended pulley radius for that belt section. The above image illustrates which dimensions we need and each is colour coded to half make.

Step 3 of HIC Universal pulleys sheaves Selection. Generally speaking V-belts fall into these classifications. Design Power Pd Transmission Power Pt Overload Coefficient Ks Calculate the Transmission Power Pt in terms of the rated.

In order to replace or install the proper belt for your pulleys you need to have an accurate measurement of the length so you can choose the right one. We will need to know the diameters of the pulleys as well as the belt length. 18022021 Pulley belts also known as V-belts are rubber belts wrapped around a set of pulleys that transmit force as an engine rotates the pulleys.

Step 2-c Calculating the Design Power2GT3GT Series. Selection of Timing Belts 1 httpfawosmisumijpFA WEBpulley us. Step 2 of HIC Universal pulleys sheaves Selection.

Selection is easy with Timing Pulleys and Belts automatic calculation tool available at. Outside diameter or the distance across the pulley when measured between groove edges.

V Belt Pulleys Selection Guide Types Features Applications Engineering360

V Belt Pulleys Selection Guide Types Features Applications Engineering360

V Belt Pulleys Selection Guide Types Features Applications Engineering360

V Belt Pulleys Selection Guide Types Features Applications Engineering360

How To Choose A Pulley That Fits Your V Belt

How To Choose A Pulley That Fits Your V Belt

How To Choose A Pulley That Fits Your V Belt

How To Choose A Pulley That Fits Your V Belt

V Belt Design Of Transmission Systems

V Belt Design Of Transmission Systems

V Belt Pulleys Selection Guide Types Features Applications Engineering360

V Belt Pulleys Selection Guide Types Features Applications Engineering360

How Does A Belt Drive Work Tec Science

How Does A Belt Drive Work Tec Science

V Belt Design Of Transmission Systems

V Belt Design Of Transmission Systems

V Belt Pulleys Selection Guide Types Features Applications Engineering360

V Belt Pulleys Selection Guide Types Features Applications Engineering360