Draw two lines perpendicularly across the back of the belt about 80 of the belt span apart or one metre apartfor very long spans. This step is not necessary if you already know your v-belt size or if the pulley and belt are greatly worn.

Industrial Pulley Ci V Belt Pulley Manufacturer From Mumbai

Industrial Pulley Ci V Belt Pulley Manufacturer From Mumbai

This way is very effective with this type of alternatorHonda Civic brake job httpsyoutube.

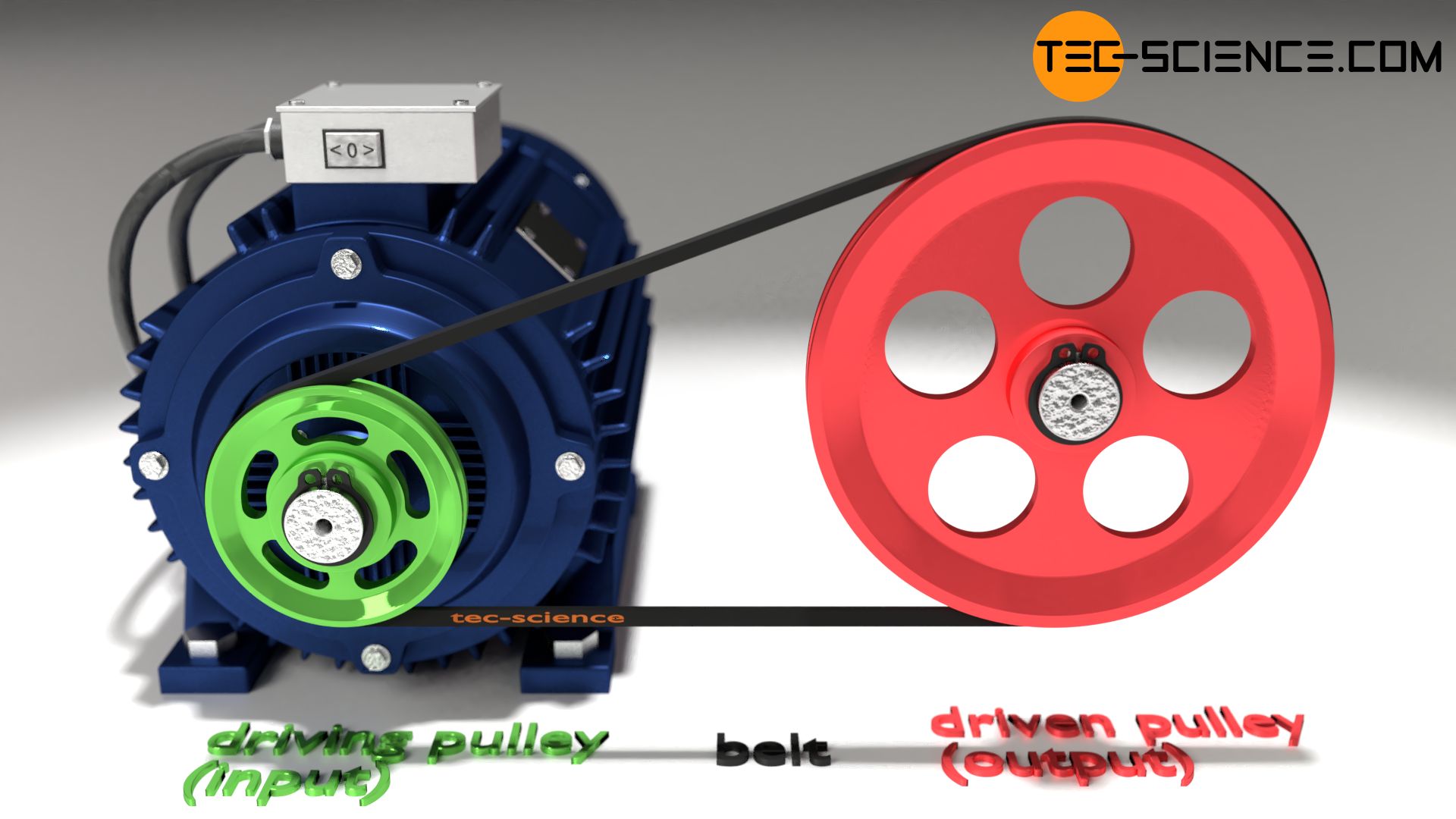

Pulling a v belt on to pulley. 18022021 Pulley belts also known as V-belts are rubber belts wrapped around a set of pulleys that transmit force as an engine rotates the pulleys. Belts can be attached around different-sized pulleys to drive shafts to change speed. The inside edge of a v belt is normally more outstretched at the base than the v shaped groove in the v belt pulley wheel allowing the grooves in the pulley and the belt to move past each other by friction.

Next well measure the pitch diameter PD this is the measurement that represents the diameter of the belt its self as it rides in the pulley. Every v belt with the exception of Harvester and Wedge belts has a 40 degree angle between its faces. They have a V.

These grooves guide the belt and allow it to gain traction. 07062019 For a belt drive system the motor torque required during constant velocity is simply the total axial force F a on the belt multiplied by the radius r 1 of the drive pulley. Or trapezoidal shaped cross section which corresponds to the shape of the pulley they rest in.

21112017 The V-belt drive technology is based on the belt tracking in a mating groove in the belt pulley. What makes a V-belt pulley stand out from other types of pulleys such as a round belt or flat pulley are the V-shaped grooves of the pulley. While working on the J.

For this installation take-up allowances must be provided to the drive. 05022018 A V-belts purpose is to transmit energy between two components. Shorten the center distance of the drive until the belts can be put on the sheaves without forcing.

Increase the distance between the two lines by 05 to 075 ie. V-belts are the most common type of belt. The more power that is transmitted the more belts and grooves in a row.

If playback doesnt begin shortly try restarting your device. Vance Planer Matcher restoration I had a flat belt pulley that I needed to get a stuck shaft removed from the hub. V belts cannot slip out of their pulleys like some of the other belts.

Removing V Belt Pulley Rust on a Rinker Boat - YouTube. This is a lesson on gear pullers. By 5mm to 75mm for an initial spacing of 1000 mm.

Refer to Tables 1 and 2 for values Tensioning the New V-Belts With the sheaves or idler moved to minimum center distance for belt removal as described above the new belts can be. The best way to install the V-Belts is to reduce the centre distance of the pulleys so much that the belts can be installed loosely. If playback doesnt begin shortly try restarting your device.

Tc torque required during constant velocity Nm Fa total axial force N r1 radius of drive pulley mm η efficiency of belt drive system. Forcing the belts can cause internal injury to the belts. Fit the belt on the pulleys with no tension.

As with gears the bigger the wheel the slower the speed. The flat belt technology is based on the high friction of the belt against the crowned belt pulleys and the transmission only contains one belt. Use of a lever invariably develops permanent twisting of belts leading to turning of belts in the pulley groove while running.

22012016 Replace Your Old-tech V-Belts With a Serpentine Pulley Setup SERP for Success. How to safely move pulley wheelsWatch all 700 of my machine shop videos. One of the main purposes of the pulley is to accommodate users with a pulley.

01042008 Now the increased overall surface material of modern belts adheres to pulley grooves through friction force to reduce the tension required to transmit torque. Fortunately measuring a pulley belt size is easy to do. This is one of the many ways of removing an alternator pulley.

As a result timing belts dont slip like other belts do so the pulleys remain in sync. It was a batt. The velocity ratio between two pulleys can be.

Next measure the wall thickness of the pulley. Ditch your 20th century V-belt drive and opt for durability and good looks in a new serpentine belt. Some mechanisms like XY gantries use timing belts and mount parts to the belts to control their position.

Run the drive under load for about 10 minutes. The common configuration shown has the crankshaft pulley driving the water pump vital for cooling and alternator charges the battery with V-belt A and the power steering pump and AC compressor driven by the crankshaft pulley and V-Belt B. V-Belts are commonly used to drive the accessories on the engine of a car.

In order to replace or install the proper belt for your pulleys you need to have an accurate measurement of the length so you can choose the right one. DIY Puller- Remove a Gear or Pulley from Motor Shaft in 15 minutes.

V Belt Pulleys Selection Guide Types Features Applications Engineering360

V Belt Pulleys Selection Guide Types Features Applications Engineering360

Jual Nbk Bushing Belt Pulley Nbk Toko Alva Standar Pulley V Alva Prima

Jual Nbk Bushing Belt Pulley Nbk Toko Alva Standar Pulley V Alva Prima

Top 8 Causes Of V Belt Failure Insight Acorn Industrial Services Ltd

Top 8 Causes Of V Belt Failure Insight Acorn Industrial Services Ltd

Lupulley 1pc Htd 5m 15t Timing Pulley 15 Teeth 16mm 21mm Belt Width Bore 12mm 5mm 6mm 6 35mm 7mm 8mm 10mm Gear Wheel Belt Pulley Pulleys Aliexpress

Lupulley 1pc Htd 5m 15t Timing Pulley 15 Teeth 16mm 21mm Belt Width Bore 12mm 5mm 6mm 6 35mm 7mm 8mm 10mm Gear Wheel Belt Pulley Pulleys Aliexpress

How Does A Belt Drive Work Tec Science

How Does A Belt Drive Work Tec Science

Jual Pulley Aluminium Puli Alumunium 6 6 Inch A1 Kota Cirebon Pulley Cirebon Tokopedia

Jual Pulley Aluminium Puli Alumunium 6 6 Inch A1 Kota Cirebon Pulley Cirebon Tokopedia

Spb V Belt Pulley Metal Stamping Parts Made Of Cast Iron 20 Year Experience Cnc Machining Use Global Sources

Spb V Belt Pulley Metal Stamping Parts Made Of Cast Iron 20 Year Experience Cnc Machining Use Global Sources

Jual Nbk Bushing Belt Pulley Nbk Toko Alva Standar Pulley V Alva Prima

Jual Nbk Bushing Belt Pulley Nbk Toko Alva Standar Pulley V Alva Prima

Belt Pulley Definiton Functions Types Parts Working Studentlesson

Belt Pulley Definiton Functions Types Parts Working Studentlesson

Amazon Com Otc 679 V Belt Pulley Pulling Attachment For Pulleys Up To 5 7 8 In Diameter Automotive

Amazon Com Otc 679 V Belt Pulley Pulling Attachment For Pulleys Up To 5 7 8 In Diameter Automotive