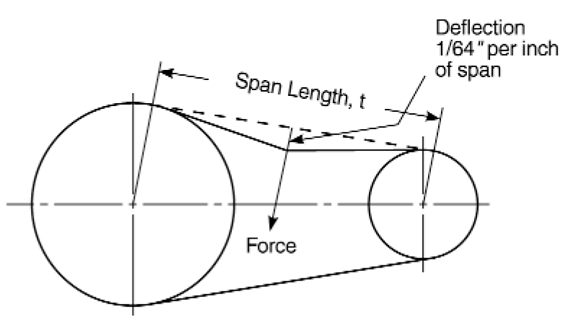

The final step is to operate the belt drive system for a few hours allowing the belts to stretch and seat properly in the pulley grooves. 09102017 With the drive stopped measure the belt span length of Forceyour drive see sketch.

V Belt Installation Tensioning Ppt Video Online Download

V Belt Installation Tensioning Ppt Video Online Download

Over tensioning shortens belt and bearing life.

How to check v belt tension. Always use a belt tension gauge that indicates static tension such as the Gates Krikit. They asked me to figure out how to use it. How you tension a belt at installation will determine how long the belt will run.

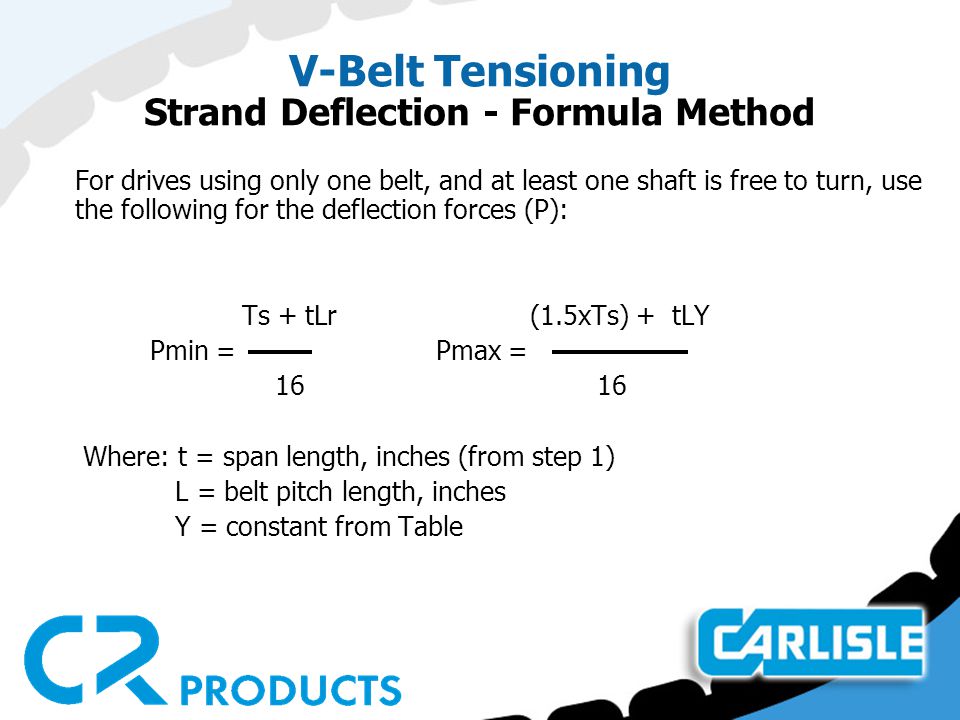

490 T m T 0 1 2 T 1 T 2. In approximate calculations it is usual to assume that the initial belt tension is equal to the mean of the driving tensions ie. Here I explain the procedure in order to have a properly tensioned belt wither it be a timing beltaltern.

05022018 3 HOW TO TENSION A V-BELT USING THE THUMB TEST The best way to do this method. 91107 for Standard Part No. 3 required belt tension.

V-Belts will transmit power satisfactorily over a wide range of tensions. 24112010 Check the belt tension. If the belt is on the point of slipping and the effects of centrifugal action are neglected T 1 T 2 e f x.

Ideal tension is the lowest tension at which the belt will not slip under peak load conditions. Tension Gauge Part No. If playback doesnt begin shortly.

2 free length span and. Set the rubber O-ring on the body of the tension gauge at the dimension equal to 164. Set the O-ring on the plunger at zero against the body of the tension gauge.

Check the tension of the belt by pushing inward on the belt with your hands. Tighten the mounting bolt to the engine accessory with the ratchet and socket. The intent is to find this proper range for any V-Belt drive.

19062013 Browning V Belt Tension Checking Procedure. Belt tension is adjusted until the belt span frequency or measured tension level is within manufacturers recommendations. 28082018 Use a ruler to check the belts tension.

Belt tension is measured by plucking the belt span while holding a sensor close by. Look for any shiny parts along the part of the belt that comes in contact with the pulleys. BELT TENSION CHECKER TENSIONING V-BELT DRIVES WITH A BROWNING TENSION CHECKER General rules of tensioning.

For every inch of span length. Too little tension results in slippage excess heat and premature belt. Make V-Drive inspection on a periodic basis.

How To Know The Correct Tension. The belt should have no more than a 12 inch of slack to be properly tensioned. 26022009 Our maintenance dept.

91132 for Micro-V to determine proper tension from the Installation Chart. However in order to optimize belt life and performance and to avoid undue stress on shafts and bearings it is desirable to calculate and measure belt tension based on drive loads. We mention the thumb test method using your hand or thumb to apply pressure to the belt as a way to judge whether or not it has the correct amount of tension because many traditional businesses still practice this style of V-belt tensioning.

There should be no more than one-half to one inch 125 centimeters to 25 centimeters of give. However there is still a wide range of tension which a belt will operate satisfactorily. Because of this a belt tension gauge is not necessary for most vehicles.

Bought a belt tension meter to testconfirm proper belt tension using frequency measurement. An experienced user can develop a feel when a drive is tensioned within this range. After looking at the procedure it became obvious that one has to know.

Check after jog start or 1-3 minutes of operation at 8 hours 24 hours. Keep belts free from foreign material which may cause slip. Check tension frequently during the first 24 hours of operation.

Instead use a ruler to measure the distance between the. For example the deflection for a 32. Do a visual check of the V-belt to see if it is cracked or worn in any spots.

Check the tension on the longest length of the belt. X 32 or 12. Tension ranges above are for drives requiring single belts.

Adjust the belt as needed from the adjustment bolt until the slack in the belt is no more than a 12 inch. In many applications the serpentine belt needs only to be reasonably tight. This indicates belt slippage.

Check tension frequently during the first 24-48 hours of run-in operation. Too much tension results in excessive stress on belts bearings and shafts. Never apply belt dressing as this will damage the belt and cause early failure.

How To Tension A V Belt How Not To Ibt Industrial Solutions Ibt Industrial Solutions

How To Tension A V Belt How Not To Ibt Industrial Solutions Ibt Industrial Solutions

V Belt Installation Tensioning Ppt Video Online Download

V Belt Installation Tensioning Ppt Video Online Download

V Belt Installation Tensioning Ppt Video Online Download

V Belt Installation Tensioning Ppt Video Online Download

Manual Belt Tension Tester Pragati Power

Manual Belt Tension Tester Pragati Power

Belt Drive Maintenance Je Bearing

How To Tension A V Belt How Not To Ibt Industrial Solutions Ibt Industrial Solutions

How To Tension A V Belt How Not To Ibt Industrial Solutions Ibt Industrial Solutions

How To Check V Belt Tension By Hand

How To Check V Belt Tension By Hand

How To Find Tension In V Belt Quickly Youtube

How To Find Tension In V Belt Quickly Youtube

3 Ways To Test Serpentine Belt Tension Wikihow

3 Ways To Test Serpentine Belt Tension Wikihow

V Belt Installation Tensioning Ppt Video Online Download

V Belt Installation Tensioning Ppt Video Online Download

3 Ways To Test Serpentine Belt Tension Wikihow

3 Ways To Test Serpentine Belt Tension Wikihow